Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ഫെബ്രു . 15, 2025 00:46

Back to list

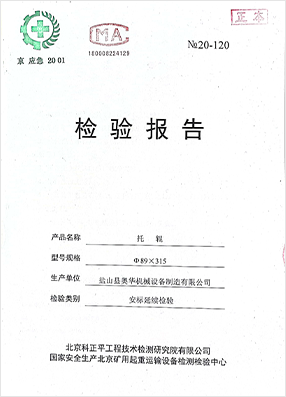

conveyor trough rollers

Conveyor trough rollers play an essential role in the intricate design and functionality of conveyor systems used across various industries. Their design and materials have evolved considerably, allowing for enhanced performance, longevity, and efficiency in material handling tasks.

In the realm of system optimization, it is crucial for industry professionals to select the right type of conveyor trough rollers. Factors such as the type of material being transported, the conveyor's load capacity, speed, and environmental conditions should guide the selection process. Consulting with experienced engineers or manufacturers ensures tailored solutions that meet specific operational requirements. For instance, operations dealing with heavy loads or abrasive materials might benefit from rollers with a robust outer shell or additional protective coatings. In contrast, industries focused on light materials might prioritize lightweight roller designs to enhance speed and energy efficiency. Such expert consultations and bespoke solutions underscore the importance of industry expertise and experience when it comes to optimizing conveyor systems. Lastly, the integration of smart technology into conveyor trough rollers marks the future of conveyor systems. This includes embedding sensors to monitor roller performance in real-time, predicting maintenance needs before they cause operational hiccups. Such innovations ensure that conveyor systems remain highly efficient while adapting to the modern industry's ever-changing demands. In conclusion, conveyor trough rollers are more than just basic components in conveyor systems; they are sophisticated products imbued with innovation and engineering expertise. Their development reflects broader trends in manufacturing and transportation industries towards efficiency, durability, and sustainability. By leveraging new materials, embracing technological advancements, and utilizing expert guidance, businesses can enhance their logistic capabilities, leading to improved productivity and reduced costs. Understanding and implementing these aspects can transform how companies approach material handling and conveyor system maintenance, establishing a competitive edge in challenging markets.

In the realm of system optimization, it is crucial for industry professionals to select the right type of conveyor trough rollers. Factors such as the type of material being transported, the conveyor's load capacity, speed, and environmental conditions should guide the selection process. Consulting with experienced engineers or manufacturers ensures tailored solutions that meet specific operational requirements. For instance, operations dealing with heavy loads or abrasive materials might benefit from rollers with a robust outer shell or additional protective coatings. In contrast, industries focused on light materials might prioritize lightweight roller designs to enhance speed and energy efficiency. Such expert consultations and bespoke solutions underscore the importance of industry expertise and experience when it comes to optimizing conveyor systems. Lastly, the integration of smart technology into conveyor trough rollers marks the future of conveyor systems. This includes embedding sensors to monitor roller performance in real-time, predicting maintenance needs before they cause operational hiccups. Such innovations ensure that conveyor systems remain highly efficient while adapting to the modern industry's ever-changing demands. In conclusion, conveyor trough rollers are more than just basic components in conveyor systems; they are sophisticated products imbued with innovation and engineering expertise. Their development reflects broader trends in manufacturing and transportation industries towards efficiency, durability, and sustainability. By leveraging new materials, embracing technological advancements, and utilizing expert guidance, businesses can enhance their logistic capabilities, leading to improved productivity and reduced costs. Understanding and implementing these aspects can transform how companies approach material handling and conveyor system maintenance, establishing a competitive edge in challenging markets.

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS