Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor roller stands

Understanding Conveyor Roller Stands Essential Components for Efficient Material Handling

In the realm of industrial manufacturing and logistics, efficient material handling plays a pivotal role in ensuring smooth operations. Among the various components that facilitate this process, conveyor roller stands have emerged as indispensable tools. These stands not only support the weight of the conveyor system but also enhance productivity by providing stability and ease of movement for goods. In this article, we will explore the importance, types, applications, and advantages of conveyor roller stands.

What are Conveyor Roller Stands?

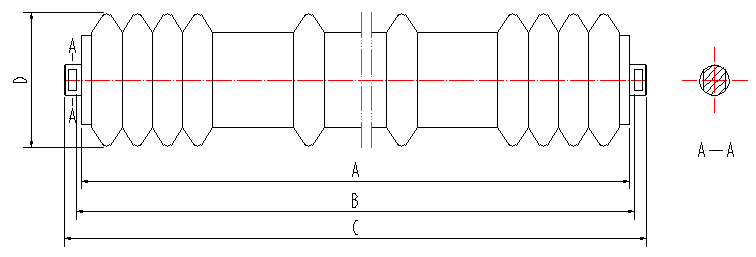

Conveyor roller stands are structures designed to support conveyor rollers, which are cylindrical components used to facilitate the movement of goods along a conveyor belt. These stands are typically adjustable, allowing for versatility in height and configuration, which is crucial for adapting to different industrial needs. The primary function of roller stands is to hold the rollers in place, ensuring that products can be transported smoothly and efficiently within a facility.

Importance of Conveyor Roller Stands

The importance of conveyor roller stands cannot be overstated. They play a crucial role in

1. Supporting Heavy Loads With industries often dealing with heavy materials, roller stands are engineered to bear significant weight without compromising structural integrity. This makes them critical for preventing system failures and ensuring safety in a busy production environment.

2. Maintaining Alignment Proper alignment of conveyor rollers is essential for smooth operations. Roller stands help maintain this alignment, minimizing friction and wear on the conveyor system while maximizing efficiency.

3. Enhancing Flexibility Adjustable roller stands allow for custom configurations, which means that they can easily adapt to different types of products and changes in production lines. This flexibility is vital for industries that often alter their operational setups.

4. Improving Safety By supporting conveyor roller systems securely, these stands help prevent accidents that could arise from shifting equipment or heavy loads falling. Ensuring a stable environment is crucial for the safety of workers and equipment alike.

Types of Conveyor Roller Stands

Conveyor roller stands come in various types, each designed for specific applications

conveyor roller stands

1. Fixed Roller Stands These are permanent installations that provide robust support for conveyor rollers. They are ideal for assembly lines where the layout remains constant.

2. Adjustable Roller Stands These stands can be modified in height and configuration, making them suitable for varied production needs and configurations. They allow for quick adjustments based on the types of products being handled.

3. Heavy-Duty Roller Stands Designed to support significantly heavy materials, these stands are constructed with reinforced materials and are often used in warehouses and heavy manufacturing environments.

4. Mobile Roller Stands Equipped with wheels, these stands enable easy relocation, providing flexibility for dynamic workspaces that require frequent rearrangements of equipment.

Applications of Conveyor Roller Stands

Conveyor roller stands find application across various sectors, including

- Manufacturing They are integral in assembly lines, helping to move parts from one station to another efficiently. - Warehousing In distribution centers, roller stands facilitate the swift movement of goods, enabling effective inventory management. - Food Processing These stands ensure that food products are handled safely and efficiently, adhering to strict industry standards.

Advantages of Using Conveyor Roller Stands

The adoption of conveyor roller stands offers several advantages, including

- Increased Efficiency By streamlining the movement of goods, roller stands contribute to faster production times and improved workflow. - Reduced Labor Costs With automation and efficient movement systems, the need for manual handling decreases, resulting in lower labor expenses. - Enhanced Durability Quality roller stands are built to withstand regular use, leading to long-term cost savings on repairs and replacements.

Conclusion

Conveyor roller stands are vital components in the landscape of material handling. By supporting the infrastructure necessary for efficient transport systems, they not only enhance productivity but also ensure safety and adaptability in various industrial settings. As industries continue to evolve and seek ways to enhance their operational efficiency, the importance of conveyor roller stands will undoubtedly grow. Investing in high-quality roller stands can lead to significant improvements in workflow, safety, and overall performance in material handling processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025