Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ജൂണ് . 19, 2024 00:35

Back to list

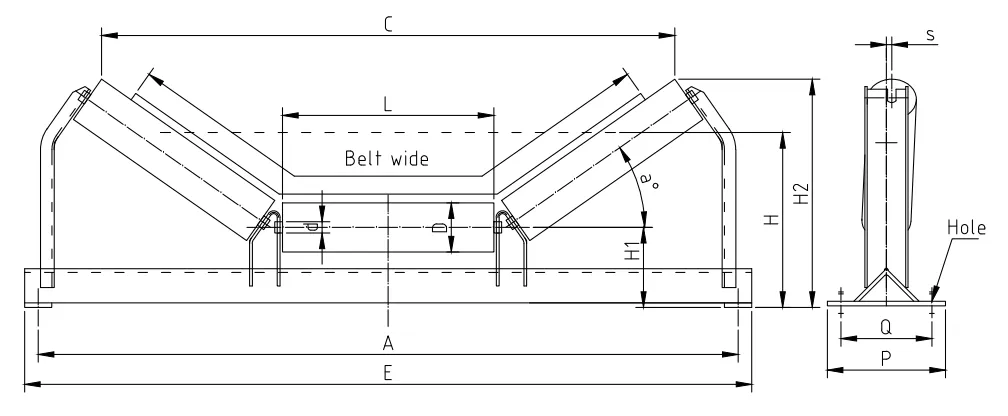

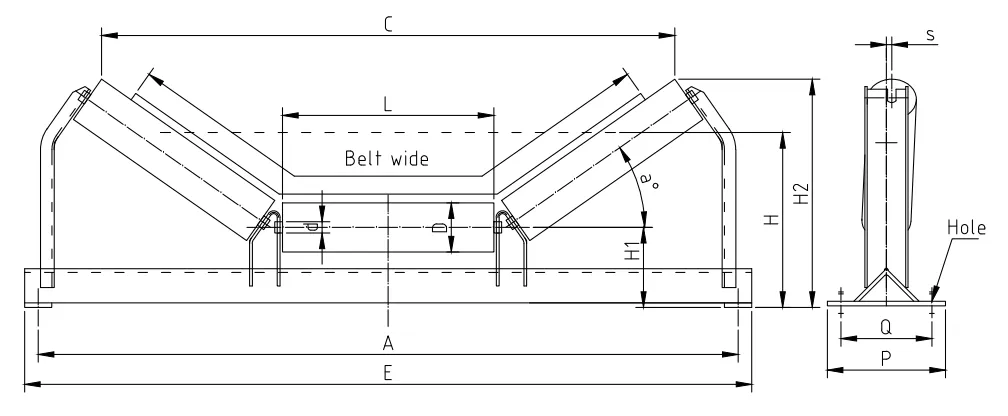

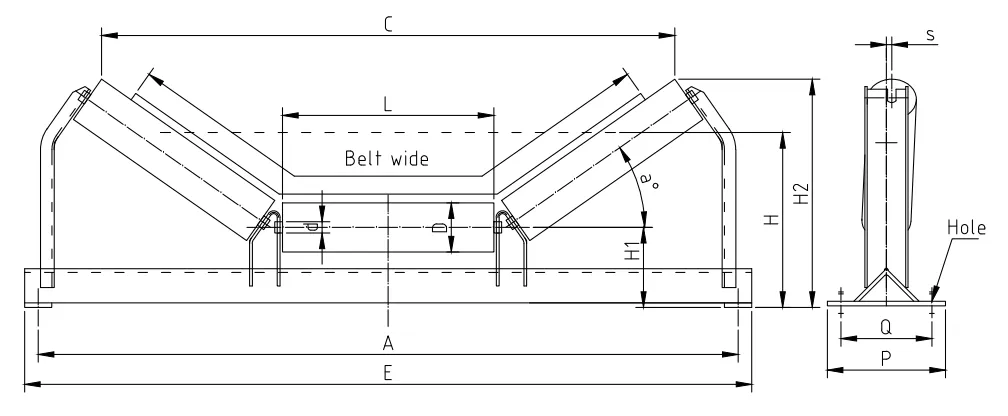

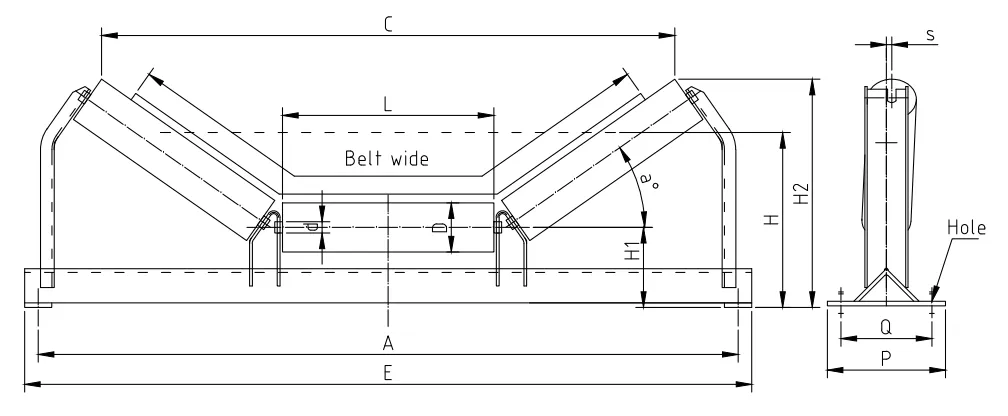

Conveyor belt support brackets installation.

Optimizing Warehouse Efficiency with Conveyor Mounting Brackets

In the fast-paced world of logistics and material handling, the importance of a well-designed conveyor system cannot be overstated. One crucial component that often goes unnoticed but significantly impacts the efficiency and stability of these systems is the humble conveyor mounting bracket. These brackets serve as the backbone of the conveyor assembly, ensuring seamless transition between different sections of the conveyor belt and providing a stable platform for the entire setup.

Conveyor mounting brackets are engineered to withstand the rigorous demands of continuous operation, supporting the weight of the conveyed items and the machinery itself. They come in various shapes and sizes, tailored to fit specific applications within warehouses, distribution centers, manufacturing plants, and other industrial settings. The brackets can be made from robust materials such as steel or aluminum, offering both strength and durability.

The design of these brackets allows for quick and easy installation while also enabling adjustments to accommodate changes in the conveyor's path or angle. This flexibility is paramount in dynamic environments where workflows might need to be altered on short notice. Moreover, some brackets feature integrated components like rollers or slide plates, which further enhance the smooth transport of goods along the conveyor belt.

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role conveyor mounting brackets. By keeping the conveyor belt properly aligned and supported, these brackets help prevent misalignment issues that could lead to premature wear and tear of the conveyor belt itself. Regular inspections of the brackets ensure they remain free from corrosion and damage, thus prolonging the lifespan of the entire conveyor system.

In addition to their functional benefits, conveyor mounting brackets can also contribute to aesthetic improvements in a facility. Well-designed brackets provide a clean, organized appearance, which not only enhances safety by reducing tripping hazards but also projects a professional image for visitors and auditors alike.

Investing in high-quality conveyor mounting brackets is investing in the seamless operation of a warehouse or manufacturing plant. As these brackets are integral to maintaining efficiency, reducing downtime, and preserving the integrity of the equipment, they should be selected with care and maintained with diligence. With the right brackets in place, businesses can ensure that their conveyor systems run smoothly, translating into optimized workflows and increased productivity.

conveyor mounting brackets. By keeping the conveyor belt properly aligned and supported, these brackets help prevent misalignment issues that could lead to premature wear and tear of the conveyor belt itself. Regular inspections of the brackets ensure they remain free from corrosion and damage, thus prolonging the lifespan of the entire conveyor system.

In addition to their functional benefits, conveyor mounting brackets can also contribute to aesthetic improvements in a facility. Well-designed brackets provide a clean, organized appearance, which not only enhances safety by reducing tripping hazards but also projects a professional image for visitors and auditors alike.

Investing in high-quality conveyor mounting brackets is investing in the seamless operation of a warehouse or manufacturing plant. As these brackets are integral to maintaining efficiency, reducing downtime, and preserving the integrity of the equipment, they should be selected with care and maintained with diligence. With the right brackets in place, businesses can ensure that their conveyor systems run smoothly, translating into optimized workflows and increased productivity.

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role

Maintenance is another critical aspect where conveyor mounting brackets play a pivotal role conveyor mounting brackets. By keeping the conveyor belt properly aligned and supported, these brackets help prevent misalignment issues that could lead to premature wear and tear of the conveyor belt itself. Regular inspections of the brackets ensure they remain free from corrosion and damage, thus prolonging the lifespan of the entire conveyor system.

In addition to their functional benefits, conveyor mounting brackets can also contribute to aesthetic improvements in a facility. Well-designed brackets provide a clean, organized appearance, which not only enhances safety by reducing tripping hazards but also projects a professional image for visitors and auditors alike.

Investing in high-quality conveyor mounting brackets is investing in the seamless operation of a warehouse or manufacturing plant. As these brackets are integral to maintaining efficiency, reducing downtime, and preserving the integrity of the equipment, they should be selected with care and maintained with diligence. With the right brackets in place, businesses can ensure that their conveyor systems run smoothly, translating into optimized workflows and increased productivity.

conveyor mounting brackets. By keeping the conveyor belt properly aligned and supported, these brackets help prevent misalignment issues that could lead to premature wear and tear of the conveyor belt itself. Regular inspections of the brackets ensure they remain free from corrosion and damage, thus prolonging the lifespan of the entire conveyor system.

In addition to their functional benefits, conveyor mounting brackets can also contribute to aesthetic improvements in a facility. Well-designed brackets provide a clean, organized appearance, which not only enhances safety by reducing tripping hazards but also projects a professional image for visitors and auditors alike.

Investing in high-quality conveyor mounting brackets is investing in the seamless operation of a warehouse or manufacturing plant. As these brackets are integral to maintaining efficiency, reducing downtime, and preserving the integrity of the equipment, they should be selected with care and maintained with diligence. With the right brackets in place, businesses can ensure that their conveyor systems run smoothly, translating into optimized workflows and increased productivity. Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS