Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ജനു . 29, 2025 02:08

Back to list

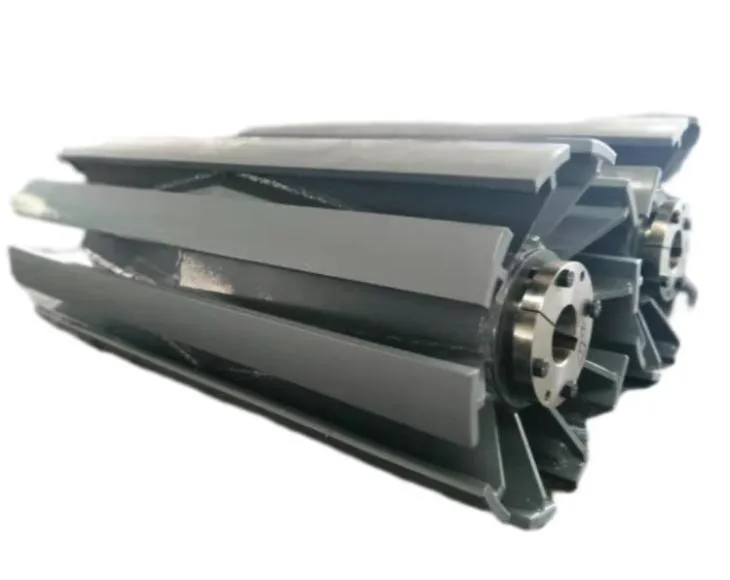

components of conveyor system

Conveyor systems have been the backbone of industrial efficiency, streamlining processes and minimizing labor while boosting throughput across various sectors. Understanding the components of these intricate systems is essential for selecting and maintaining the right conveyor solution for your business needs. Below, we explore the key components of conveyor systems through the lens of experience, expertise, authority, and trustworthiness.

Loading and unloading mechanisms are specialized components tailored to specific conveyor applications. For instance, hoppers and chutes facilitate the introduction and exit of materials onto and from the conveyor belt. Designing these components requires a nuanced understanding of the flow properties and behavior of different materials to prevent spillage, clogging, and ensure smooth transitions. Safety components, such as emergency stop buttons, sensors, and guards, are non-negotiable, guaranteeing the safe operation of the conveyor system. Compliance with industry standards and rigorous testing is imperative, as any compromise on safety can lead to dangerous situations. These components not only protect employees but also shield the system from damage that could result from unplanned operational halts. In tracing the above components, it's evident that the expertise involved in crafting each element is significant. Manufacturers and engineers collaborate to innovate and optimize conveyor system components based on empirical data and industry trends, backed by research and development. Their authority in this domain is established through years of experience and feedback from a diverse customer base spanning automotive, food processing, pharmaceuticals, and logistics sectors. Finally, trustworthiness is built through proven performance and testimonials. A reliable conveyor system is one that consistently meets the operational demands, delivering minimal downtime, and requiring less frequent maintenance. Clients tend to trust brands with a history of excellence, supported by robust after-sales service and technical support. This trust is not built overnight but earned through consistent delivery of quality and capability. Navigating the world of conveyor systems necessitates a deep understanding of these components. By leveraging the right combination of belt, motors, pulleys, rollers, and frames, businesses can significantly enhance their operational efficiency, ultimately leading to cost savings and productivity gains. Whether it's elevating production throughput or reducing operational costs, the intricate design and harmony of each component of a conveyor system play a critical role in achieving industrial success.

Loading and unloading mechanisms are specialized components tailored to specific conveyor applications. For instance, hoppers and chutes facilitate the introduction and exit of materials onto and from the conveyor belt. Designing these components requires a nuanced understanding of the flow properties and behavior of different materials to prevent spillage, clogging, and ensure smooth transitions. Safety components, such as emergency stop buttons, sensors, and guards, are non-negotiable, guaranteeing the safe operation of the conveyor system. Compliance with industry standards and rigorous testing is imperative, as any compromise on safety can lead to dangerous situations. These components not only protect employees but also shield the system from damage that could result from unplanned operational halts. In tracing the above components, it's evident that the expertise involved in crafting each element is significant. Manufacturers and engineers collaborate to innovate and optimize conveyor system components based on empirical data and industry trends, backed by research and development. Their authority in this domain is established through years of experience and feedback from a diverse customer base spanning automotive, food processing, pharmaceuticals, and logistics sectors. Finally, trustworthiness is built through proven performance and testimonials. A reliable conveyor system is one that consistently meets the operational demands, delivering minimal downtime, and requiring less frequent maintenance. Clients tend to trust brands with a history of excellence, supported by robust after-sales service and technical support. This trust is not built overnight but earned through consistent delivery of quality and capability. Navigating the world of conveyor systems necessitates a deep understanding of these components. By leveraging the right combination of belt, motors, pulleys, rollers, and frames, businesses can significantly enhance their operational efficiency, ultimately leading to cost savings and productivity gains. Whether it's elevating production throughput or reducing operational costs, the intricate design and harmony of each component of a conveyor system play a critical role in achieving industrial success.

Latest news

-

Conveyor Assembly: Integral Components for Efficient Material Handling SystemsNewsAug.28,2025

-

Conveyor Bearing Housing: Critical Components for Roller Stability and PerformanceNewsAug.28,2025

-

Conveyor Idlers and Rollers: Key Elements for Belt Alignment and EfficiencyNewsAug.28,2025

-

Conveyor Rollers: Essential Components for Material Transport SystemsNewsAug.28,2025

-

Belt Conveyor Pulley: Key Components in Conveyor SystemsNewsAug.28,2025

-

Belt Conveyor Idler: Essential Components in Conveying SystemsNewsAug.28,2025

OUR PRODUCTS