Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 10, 2025 10:11

Back to list

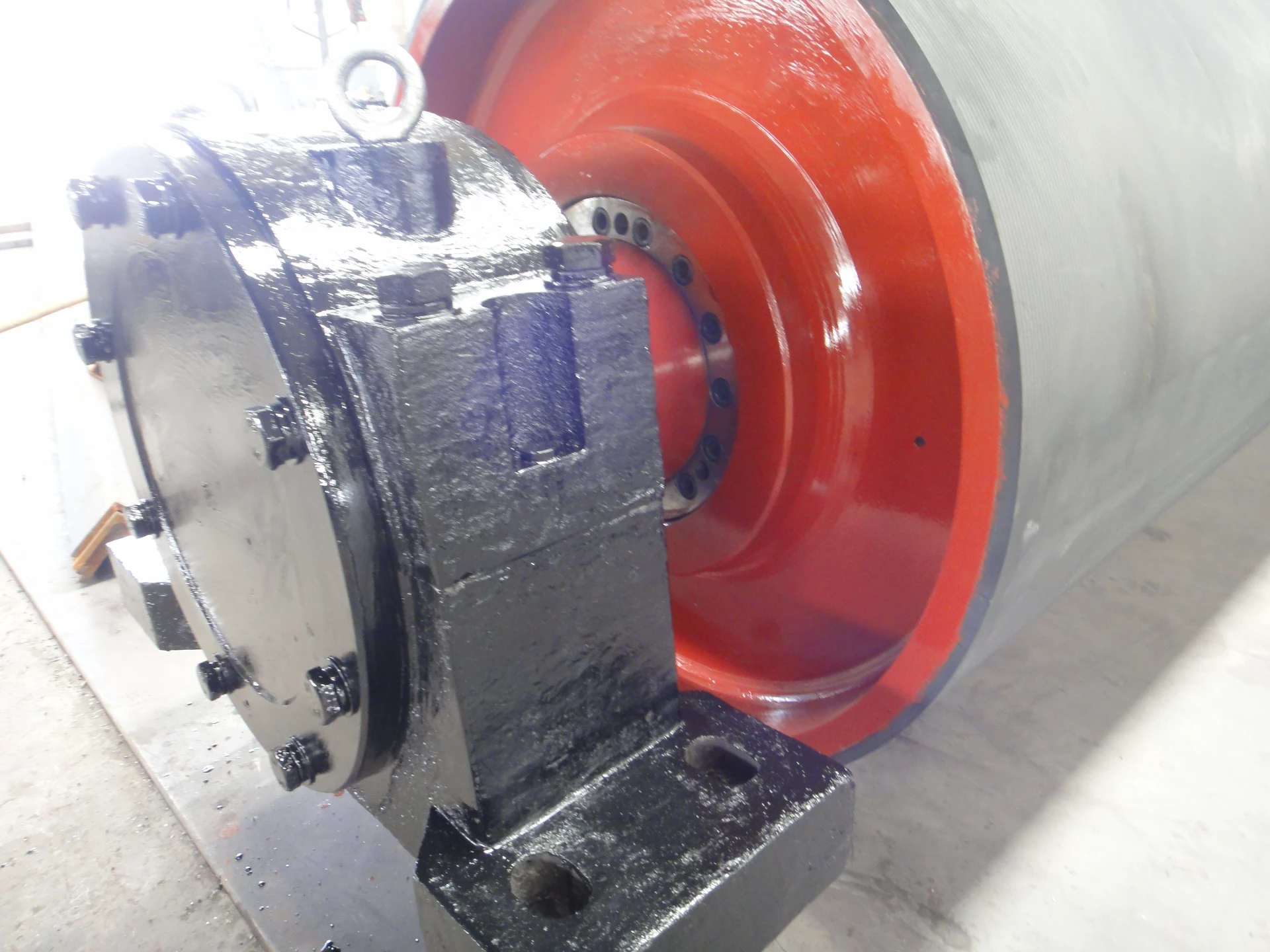

Friction Aligning Idler

Urethane idler rollers, often overshadowed by their metal and rubber counterparts, have revolutionized various industries with their unique properties. Understanding these rollers' benefits can greatly enhance the efficiency and longevity of your production line, making them an invaluable resource for businesses seeking effective conveying solutions.

From an environmental standpoint, urethane presents an eco-friendly option due to its long service life, reducing the frequency of material disposal. Additionally, many manufacturers offer recycling programs for urethane products, further contributing to sustainable operation practices. The adaptability of urethane idler rollers also lies in their customizable nature. Manufacturers can produce urethane rollers in various diameters, lengths, and hardness levels to suit specific applications. This customizability ensures businesses can precisely match roller specifications with their operational needs, maximizing efficiency and throughput. Selecting the right urethane roller supplier is essential and should focus on partners with a proven track record of quality and reliability. Verified industry certifications and rigorous quality control measures contribute to product consistency, providing businesses with confidence in their investment. Collaborating with specialized manufacturers also offers access to technical expertise that can assist in selecting the optimal roller configuration, enhancing overall operational performance. To validate these benefits, numerous case studies highlight significant improvements in production efficiency and cost savings post-implementation of urethane idler rollers. In one study, a beverage company reported a 20% increase in their production line speed while decreasing downtime by 15%, attributing these improvements to the switch from traditional rubber rollers to urethane counterparts. In conclusion, urethane idler rollers present a compelling solution for businesses seeking durable, efficient, and adaptable materials for their conveying systems. Their resilience, application diversity, and environmental advantages make them a favored choice across diverse industries, offering a competitive edge in demanding production environments. When chosen wisely, these rollers significantly contribute to the optimization of operational processes and the sustainable growth of industrial operations.

From an environmental standpoint, urethane presents an eco-friendly option due to its long service life, reducing the frequency of material disposal. Additionally, many manufacturers offer recycling programs for urethane products, further contributing to sustainable operation practices. The adaptability of urethane idler rollers also lies in their customizable nature. Manufacturers can produce urethane rollers in various diameters, lengths, and hardness levels to suit specific applications. This customizability ensures businesses can precisely match roller specifications with their operational needs, maximizing efficiency and throughput. Selecting the right urethane roller supplier is essential and should focus on partners with a proven track record of quality and reliability. Verified industry certifications and rigorous quality control measures contribute to product consistency, providing businesses with confidence in their investment. Collaborating with specialized manufacturers also offers access to technical expertise that can assist in selecting the optimal roller configuration, enhancing overall operational performance. To validate these benefits, numerous case studies highlight significant improvements in production efficiency and cost savings post-implementation of urethane idler rollers. In one study, a beverage company reported a 20% increase in their production line speed while decreasing downtime by 15%, attributing these improvements to the switch from traditional rubber rollers to urethane counterparts. In conclusion, urethane idler rollers present a compelling solution for businesses seeking durable, efficient, and adaptable materials for their conveying systems. Their resilience, application diversity, and environmental advantages make them a favored choice across diverse industries, offering a competitive edge in demanding production environments. When chosen wisely, these rollers significantly contribute to the optimization of operational processes and the sustainable growth of industrial operations.

Next:

Latest news

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025

OUR PRODUCTS