Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu mining conveyor pulleys

Mining Conveyor Pulleys Essential Components for Efficient Operations

In the mining industry, efficiency and reliability are paramount. One of the critical components that ensure smooth operations in material handling systems is the conveyor pulley. These pulleys play a vital role in the transportation of mined materials, from the extraction point to processing facilities, making them indispensable in mining operations.

Understanding Conveyor Pulleys

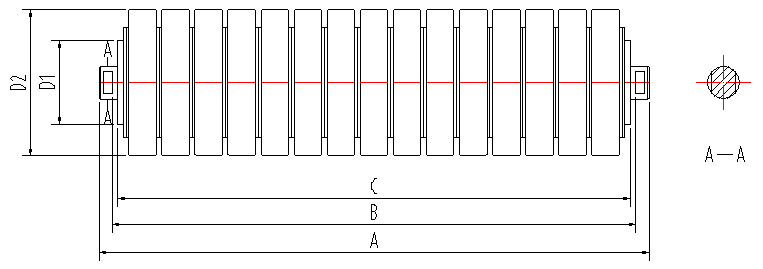

Conveyor pulleys are cylindrical devices used to drive, redirect, or support belts in a conveyor system. They are typically made from robust materials such as steel to withstand the harsh conditions commonly found in mining environments. There are several types of conveyor pulleys, each designed for specific functions, including drive pulleys, bend pulleys, and take-up pulleys.

Drive Pulleys play a crucial role in providing the necessary force to move the conveyor belt. They are usually positioned at the end of a conveyor system and are equipped with a motor that drives the belt forward. Bend Pulleys assist in changing the direction of the conveyor belt, while Take-Up Pulleys are essential for maintaining belt tension, ensuring optimal performance and minimizing wear and tear.

Durability and Maintenance

Given their exposure to heavy loads, abrasive materials, and extreme conditions, mining conveyor pulleys must be incredibly durable. High-quality pulleys are designed to resist corrosion and wear, which minimizes downtime and maintenance costs. Regular inspections and maintenance are critical to ensure the longevity of the pulleys. Common maintenance practices include greasing bearings, checking for alignment, and monitoring belt tension to prevent equipment failure.

mining conveyor pulleys

Innovations in Pulley Design

Recent advancements in technology have led to innovative designs that enhance the efficiency and performance of conveyor pulleys. For instance, some manufacturers are now producing lightweight yet strong composite pulleys that reduce the overall weight of the conveyor system, leading to lower energy consumption. Additionally, advanced coating technologies can increase resistance to wear and corrosion, further extending the life expectancy of the pulleys.

Environmental Considerations

As the mining industry moves towards more sustainable practices, the design and operation of conveyor pulleys are also evolving. Modern systems are designed to minimize energy consumption and reduce carbon footprints. This includes integrating energy-efficient motors and using materials that are more environmentally friendly. Such changes not only improve operational efficiency but also demonstrate the industry’s commitment to sustainability.

Conclusion

In conclusion, mining conveyor pulleys are critical to the efficiency and reliability of material handling systems in the mining sector. Their durable design, coupled with regular maintenance and innovative advancements, ensures the continuous operation and longevity of conveyor systems. As the industry evolves, so too will the technology and techniques associated with mining conveyor pulleys, reinforcing their status as essential components in the quest for efficient mining operations.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025