Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Vas . 16, 2025 12:08

Back to list

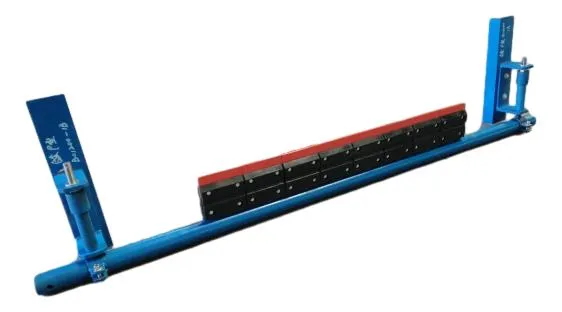

Friction Aligning Idler

Idler rollers are pivotal components in the conveyor industry, playing an integral role in ensuring efficiency and reliability in material handling processes. With a focus on experience, expertise, authoritativeness, and trustworthiness, this article delves into the specifics of idler rollers, their functionality, and their application in industrial setups.

Trustworthiness in idler roller manufacturing and application comes from a combination of real-world experience and rigorous testing. Testimonials and case studies from various industries highlight the practical benefits achieved through the use of high-quality idler rollers. Such anecdotal evidence supports the theoretical claims of extended belt life, reduced energy consumption, and decreased operational costs. Furthermore, regular audits and rigorous quality checks bolster the reputation of manufacturers who focus on producing dependable products. Testing involves simulations of actual working conditions to evaluate performance and identify potential points of failure. This comprehensive approach ensures that the idler rollers meet the expectations of clients and withstand the harshest of conditions. The capacity to innovate is also a significant component of maintaining expertise, with many manufacturers developing idler rollers that incorporate smart technologies for real-time monitoring and predictive maintenance. These innovations ensure that operators can pre-emptively address issues, thus avoiding unexpected disruptions that can be costly. In conclusion, idler rollers are critical in ensuring the seamless operation of conveyor systems across a multitude of industrial sectors. Their ability to support loads, reduce energy consumption, and withstand harsh environmental conditions make them invaluable. Through constant innovation, adherence to industry standards, and a commitment to quality, idler roller manufacturers continue to advance the efficiency and reliability of material handling processes. Trust in their expertise is well-placed, given the essential role that these components play in modern industry.

Trustworthiness in idler roller manufacturing and application comes from a combination of real-world experience and rigorous testing. Testimonials and case studies from various industries highlight the practical benefits achieved through the use of high-quality idler rollers. Such anecdotal evidence supports the theoretical claims of extended belt life, reduced energy consumption, and decreased operational costs. Furthermore, regular audits and rigorous quality checks bolster the reputation of manufacturers who focus on producing dependable products. Testing involves simulations of actual working conditions to evaluate performance and identify potential points of failure. This comprehensive approach ensures that the idler rollers meet the expectations of clients and withstand the harshest of conditions. The capacity to innovate is also a significant component of maintaining expertise, with many manufacturers developing idler rollers that incorporate smart technologies for real-time monitoring and predictive maintenance. These innovations ensure that operators can pre-emptively address issues, thus avoiding unexpected disruptions that can be costly. In conclusion, idler rollers are critical in ensuring the seamless operation of conveyor systems across a multitude of industrial sectors. Their ability to support loads, reduce energy consumption, and withstand harsh environmental conditions make them invaluable. Through constant innovation, adherence to industry standards, and a commitment to quality, idler roller manufacturers continue to advance the efficiency and reliability of material handling processes. Trust in their expertise is well-placed, given the essential role that these components play in modern industry.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS