Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Functionality and Design of Troughing Idlers in Belt Conveyor Systems

Understanding Belt Conveyor Troughing Idlers

Belt conveyor systems are essential components in material handling across industries such as mining, agriculture, and manufacturing. One of the critical elements of these systems is the troughing idler, a vital component that impacts the efficiency and functionality of belt conveyors. This article delves into the significance of troughing idlers, their design, and their operational benefits.

What Are Troughing Idlers?

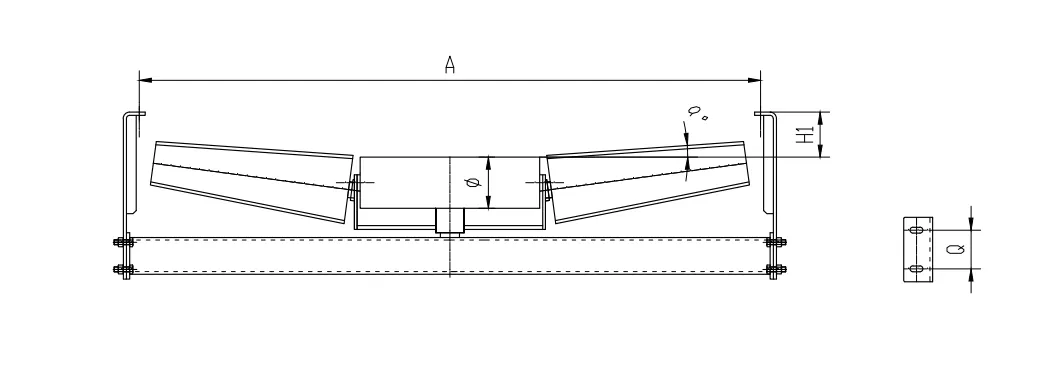

Troughing idlers are cylindrical rollers positioned at certain points along a belt conveyor to support the conveyor belt as it moves material from one location to another. What sets them apart is their unique design they are usually arranged in a V-shape or trough configuration. This design allows the idlers to stabilize the load on the conveyor belt, preventing materials from slipping off during transit.

Design and Structure

Troughing idlers are typically composed of several key components, including the roller, frame, and bearing. The roller can be made from various materials such as steel or plastic, depending on the specific application and material being transported. The frame supports the rollers and ensures they maintain the correct angle for optimal performance.

The angle of the troughing idlers can vary, commonly seen in 20°, 30°, and 45° configurations. This adjustable angle is crucial, as it allows companies to tailor the system according to the nature of the materials being handled. These variations help in optimizing the load-carrying capacity while minimizing the wear and tear on the conveyor belt itself.

Key Benefits of Troughing Idlers

belt conveyor troughing idlers

1. Material Containment One of the primary advantages of troughing idlers is their ability to contain loose materials. The trough shape provides a natural barrier that helps keep bulk materials securely on the belt, significantly reducing spillage during transportation.

2. Reduced Wear and Tear Troughing idlers help to distribute the load evenly across the conveyor belt. This uniform load distribution reduces tension and wear on the belt, prolonging its life and decreasing the frequency of necessary replacements.

3. Improved Stability The design of troughing idlers enhances the stability of the conveyor system. By supporting the belt on a wider surface area, they help maintain its shape and alignment, particularly in high-load scenarios.

4. Versatile Applications Troughing idlers are versatile and can be used in various applications, including transporting coal, grains, ores, and other bulk materials. Their adaptability makes them suitable for both heavy-duty industrial applications and lighter materials.

5. Maintenance Efficiency The modular design of troughing idlers allows for easy replacement and maintenance. If a roller becomes damaged or worn, it can be swiftly replaced without the need for extensive downtime.

Conclusion

Troughing idlers are a fundamental aspect of belt conveyor systems, offering critical support and efficiency for bulk material handling. Their unique design enhances material containment, reduces wear and tear, and ensures the stability of the conveyor system. As industries continue to rely on efficient material handling solutions, the importance of high-quality troughing idlers will only grow. Investing in durable and correctly configured troughing idlers can lead to significant operational efficiencies, making them indispensable in modern material handling.