Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Benefits and Applications of Rubber Pulleys in Mechanical Systems

The Versatility of Rubber Pulleys An Essential Component in Modern Machinery

In the rapidly evolving world of technology and manufacturing, the efficiency and effectiveness of machinery play a pivotal role in optimizing production processes. Among the myriad of components that contribute to machinery's operational capabilities, rubber pulleys stand out for their versatility and reliability. These seemingly simple components serve crucial functions across various industries, helping to drive systems with enhanced performance and durability.

Understanding Rubber Pulleys

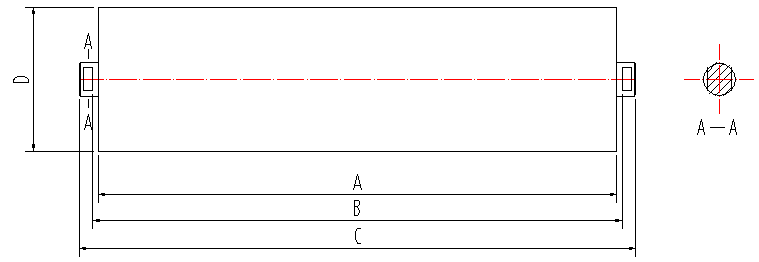

Rubber pulleys are circular components typically made from high-quality rubber compounds, which provide a balance of flexibility, resilience, and strength. These pulleys can be found in numerous applications such as conveyor systems, automotive engines, and industrial machinery. Their primary function is to redirect and transmit power from one part of a machine to another, aiding in the smooth operation of conveyor belts, belts drives, and other mechanical systems.

Advantages of Rubber Pulleys

One of the most significant advantages of rubber pulleys is their ability to reduce noise and vibration during operation. Unlike metal pulleys, which can generate considerable noise when in motion, rubber pulleys absorb shocks and dampen vibrations, creating a more pleasant working environment and reducing wear and tear on associated machinery. This quality makes rubber pulleys particularly valuable in industries where noise reduction is crucial, such as in food processing or in any workplace focusing on creating a conducive environment.

Another benefit is their lightweight nature. Rubber pulleys are significantly lighter than their metal counterparts, making them easier to handle during installation and maintenance. This lightweight characteristic also contributes to energy efficiency, as less energy is required to accelerate and decelerate lighter pulleys. Additionally, the flexibility of rubber allows for better grip on belts, reducing slippage and ensuring efficient power transmission.

Applications in Various Industries

rubber pulley

Rubber pulleys are employed across a wide range of industries, showcasing their adaptability and importance. In the automotive sector, rubber pulleys are commonly used in engine belt systems to drive essential functions like charging the battery, running the air conditioning, and powering the water pump. Their resistance to heat and wear makes them suitable for these demanding applications.

In manufacturing and logistics, rubber pulleys are integral to conveyor systems. These systems rely on the smooth operation of pulleys to transport materials efficiently. The non-slip surface of rubber pulleys ensures that items are moved without mishaps, enhancing overall productivity.

Additionally, rubber pulleys are prevalent in the textile industry, where they facilitate the operation of machines that produce fabrics and garments. The gentle yet firm grip of rubber pulleys on textile belts is vital to maintaining the integrity of delicate materials while ensuring that production flows seamlessly.

Maintenance and Longevity

While rubber pulleys are designed to withstand significant wear over time, proper maintenance is essential to prolong their lifespan. Regular inspections to check for signs of wear and tear, such as cracks or deformities, can help in identifying potential issues before they escalate. Moreover, ensuring that the pulleys are aligned correctly and operating within their specified load limits can prevent premature failure.

Conclusion

In conclusion, rubber pulleys are a vital yet often overlooked component of modern machinery that contributes significantly to efficiency, durability, and operational excellence. Their unique properties allow for effective power transmission while minimizing noise and vibration, making them indispensable across various industries. As technology continues to advance, the role of rubber pulleys will undoubtedly evolve, but their fundamental value in enhancing machine performance will remain. Whether in automotive systems, conveyor belts, or industrial machinery, rubber pulleys will continue to drive innovation and efficiency in the manufacturing landscape.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025