Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Concept of Return Idle Bracket in Financial Analysis

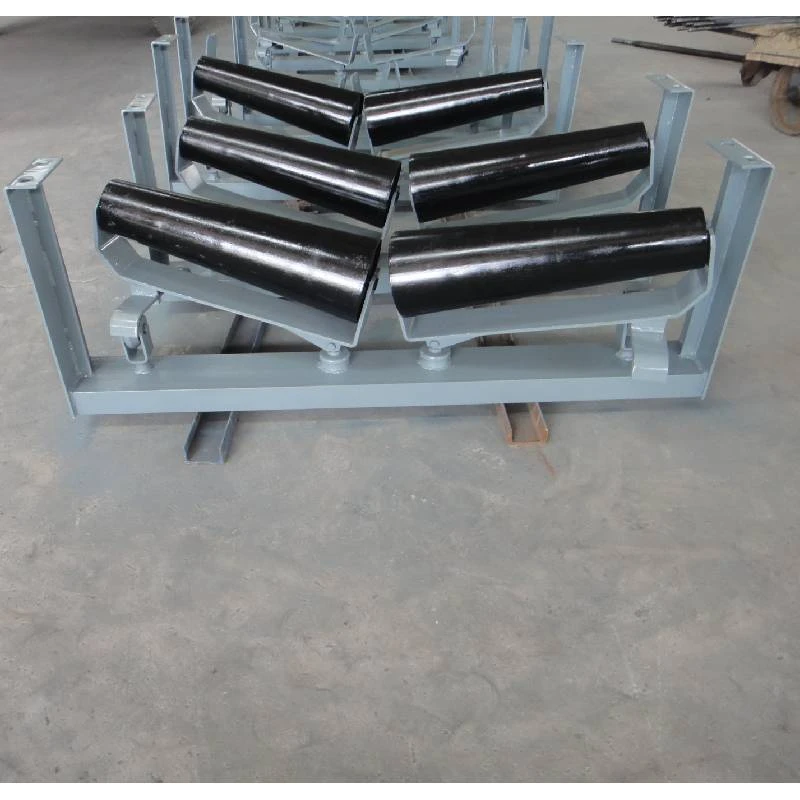

Understanding the Return Idler Bracket in Conveyor Systems

In the realm of conveyor systems, one often encounters various components designed to enhance efficiency and functionality. Among these components, the return idler bracket plays a crucial role. This article aims to elucidate the concept of the return idler bracket, its functions, and its significance in conveyor systems.

A return idler is an essential part of a conveyor belt system. Its primary function is to support the conveyor belt when it returns to the head section after discharging its load. Typically located on the return side of the conveyor, the return idlers help maintain the belt's alignment and prevent sagging, which can lead to operational inefficiencies or even failures.

The return idler bracket is the structural component that holds the return idler in place. It is usually fabricated from robust materials such as steel or reinforced plastic, ensuring it can withstand the forces exerted during belt operation. The design of the return idler bracket is critical; it must securely support the idler while allowing for some degree of movement or adjustment to accommodate belt tension and alignment changes.

One of the most notable benefits of return idler brackets is their contribution to the overall efficiency of the conveyor system

. By ensuring that the idlers remain aligned and properly tensioned, these brackets help reduce wear and tear on the conveyor belt. This reduction in friction is vital not only for prolonging the life of the belt but also for maintaining optimal operational speeds, which can significantly enhance productivity.return idler bracket

Moreover, return idler brackets can also play a role in safety. Properly maintained and installed return idlers can help prevent belt misalignment, which is a common cause of accidents in conveyor operations. Misaligned belts can lead to unexpected material spillage, equipment damage, or even personal injury. Therefore, investing in high-quality return idler brackets and ensuring their proper maintenance can promote a safer working environment.

In addition to safety and efficiency, the return idler bracket can also contribute to the overall maintenance of a conveyor system. Many modern brackets come with features that make them easier to inspect and maintain. For instance, some designs allow for quick adjustments without the need for specialized tools. This user-friendly aspect is particularly beneficial in industrial settings where downtime can be costly.

When it comes to selecting the right return idler bracket for a conveyor system, various factors must be considered. The type of materials being transported, the weight of the load, and the operational environment all play a role in determining the appropriate bracket design. Additionally, compatibility with existing conveyor components is essential to ensure seamless integration.

In conclusion, return idler brackets are integral components of conveyor systems that significantly enhance their functionality and reliability. By ensuring proper alignment and support for return idlers, these brackets contribute to increased efficiency, safety, and ease of maintenance. As industries continue to evolve and demand higher productivity, understanding and utilizing quality return idler brackets will remain paramount in optimizing conveyor operations. Investing in the right components can lead to substantial long-term benefits, making the return idler bracket an unsung hero in the world of material handling and conveyor systems.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025