Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ಮಾರ್ಚ್ . 07, 2025 04:40

Back to list

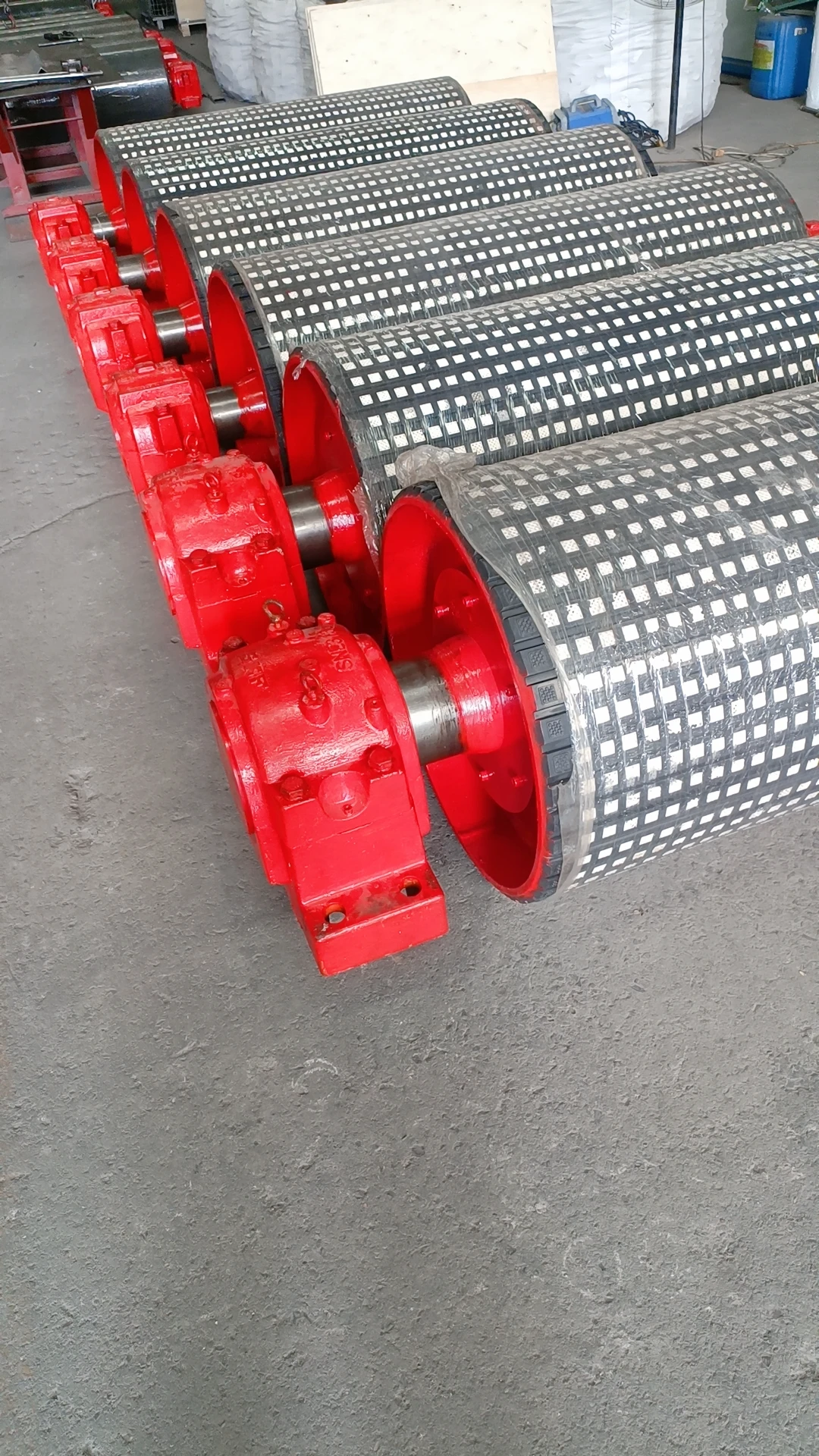

idler rollers for belt conveyors

Drive rollers for conveyors are quite simply the unsung heroes of the industrial world, combined with precision engineering, they represent the backbone of efficient material handling systems. Their contribution forms an integral component of modern automated conveyor systems, indispensable in factories, warehouses, and distribution centers globally. This article delves into the critical facets of drive rollers, emphasizing the expert knowledge, experience, authority, and trustworthiness they encapsulate within today's industrial landscape.

Trustworthiness stems from the legacy of hard-earned reputations, as top-tier manufacturers often draw upon decades of accumulated expertise. They cultivate strong client relationships by providing comprehensive after-sales support, including installation guidance and maintenance training. Trust is further engendered through transparent product dissemination, where detailed specifications, CAD models, and documented case studies offer a window into the drive roller's lifecycle and its impact on system efficiency. Real-world experience attests to the significance of regular assessments and simulations in optimizing drive roller performance. Implementing preventive maintenance protocols informed by thorough data analytics enhances operational lifespan and betters predictive maintenance schemes. This systemic approach positions clients not only to resolve current challenges but also to anticipate future needs, ensuring the longevity of conveyor systems and the consistent movement of goods. In conclusion, the strategic selection and application of drive rollers for conveyors reflect expert knowledge and experience combined with authoritative design and manufacturing excellence. Their foundational role in modern industrial processes underscores the combination of innovation, engineering, and trust that defines success in today's competitive market. This narrative affirms drive rollers not merely as components but as pivotal contributors to operational resilience and business advancement.

Trustworthiness stems from the legacy of hard-earned reputations, as top-tier manufacturers often draw upon decades of accumulated expertise. They cultivate strong client relationships by providing comprehensive after-sales support, including installation guidance and maintenance training. Trust is further engendered through transparent product dissemination, where detailed specifications, CAD models, and documented case studies offer a window into the drive roller's lifecycle and its impact on system efficiency. Real-world experience attests to the significance of regular assessments and simulations in optimizing drive roller performance. Implementing preventive maintenance protocols informed by thorough data analytics enhances operational lifespan and betters predictive maintenance schemes. This systemic approach positions clients not only to resolve current challenges but also to anticipate future needs, ensuring the longevity of conveyor systems and the consistent movement of goods. In conclusion, the strategic selection and application of drive rollers for conveyors reflect expert knowledge and experience combined with authoritative design and manufacturing excellence. Their foundational role in modern industrial processes underscores the combination of innovation, engineering, and trust that defines success in today's competitive market. This narrative affirms drive rollers not merely as components but as pivotal contributors to operational resilience and business advancement.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS