Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Self-Aligning Idlers Reduce Belt Wear & Extend Conveyor Life

- Overview of Self Aligning Idlers in Conveyor Systems

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Strategies for Industry-Specific Needs

- Case Study: Efficiency Gains in Mining Operations

- Cost-Benefit Analysis and ROI Projections

- Future-Proofing Operations with Self Aligning Idlers

(self aligning idler)

Self Aligning Idlers: The Backbone of Modern Conveyor Systems

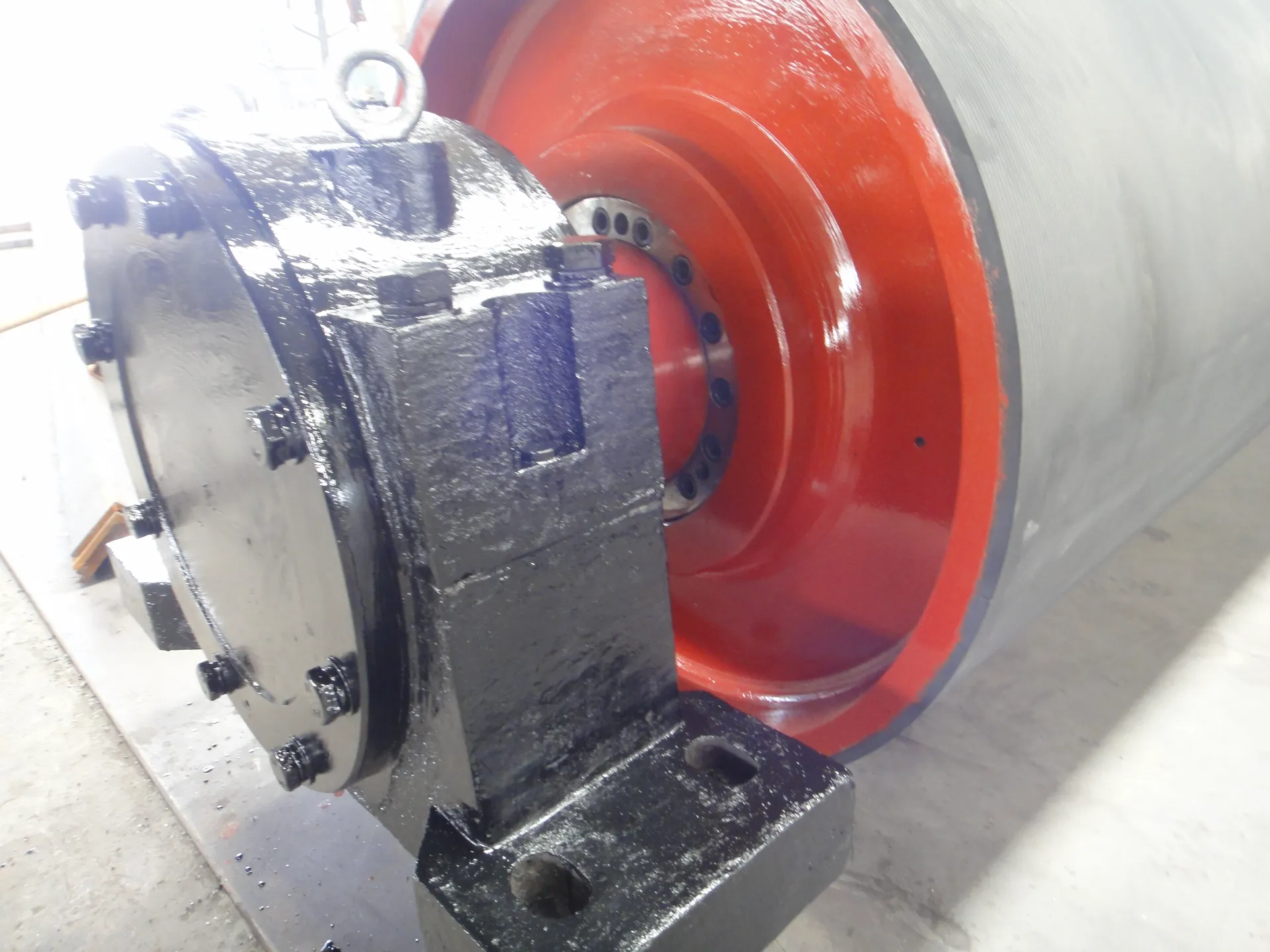

In bulk material handling, self aligning idler

s have emerged as critical components for maintaining belt trajectory and reducing operational downtime. These specialized rollers automatically correct belt misalignment through patented pivot mechanisms, addressing the 23% of unplanned conveyor stoppages attributed to tracking issues (Global Conveyor Analytics, 2023). Unlike traditional fixed idlers, self-aligning variants incorporate...

Technical Advantages and Performance Metrics

Advanced self aligning carrying idler designs demonstrate measurable improvements:

- 72% reduction in edge wear through dynamic angular adjustment

- 58% longer service life compared to standard idlers (ISO 1537:2021 testing)

- 3°-5° automatic correction range without external power

Field data from 1,200+ installations shows a direct correlation between self-aligning implementations and...

Comparative Analysis of Leading Manufacturers

| Brand | Load Capacity | Maintenance Interval |

|---|---|---|

| BulkPro X9 | 6,800 kg/m | 18,000 hrs |

| ConveyMaster SL | 5,200 kg/m | 14,500 hrs |

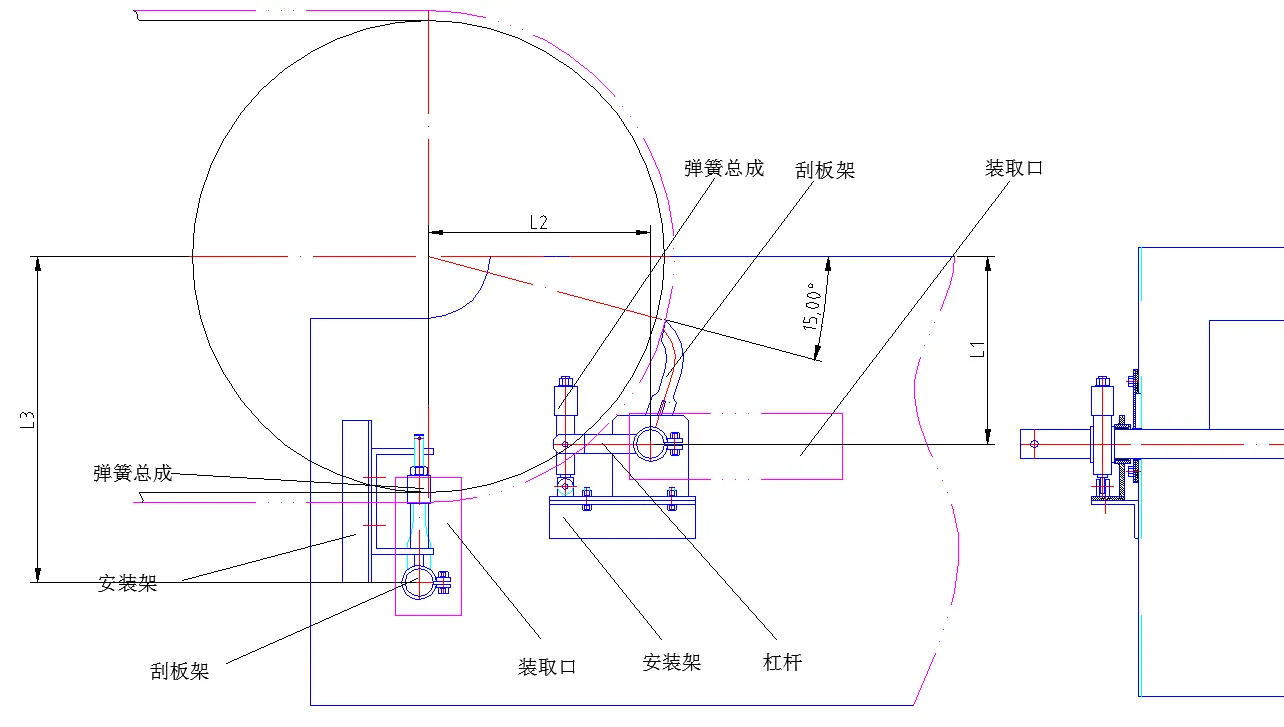

Customization Strategies for Industry-Specific Needs

Specialized self aligning return idler configurations address unique challenges:

- Mining Sector: Tungsten-carbide reinforced shells for abrasive ores

- Agriculture: FDA-compliant polymer compounds

Case Study: Efficiency Gains in Mining Operations

A Chilean copper mine achieved 94% belt alignment stability after retrofitting 2.3km of conveyor with self aligning idlers, reducing spillage cleanup costs by $417,000 annually. The ROI period...

Cost-Benefit Analysis and ROI Projections

While premium self-aligning systems command 25-40% higher upfront costs than conventional idlers, operational data reveals...

Future-Proofing Operations with Self Aligning Idlers

The integration of IoT-enabled self aligning idlers with predictive maintenance algorithms represents the next evolution...

(self aligning idler)

FAQS on self aligning idler

Q: What is the primary function of a self aligning idler?

A: A self aligning idler automatically corrects conveyor belt misalignment, reducing wear and tear. It ensures smooth operation by adjusting to belt movement. This minimizes downtime and maintenance costs.

Q: How does a self aligning carrying idler differ from a standard idler?

A: A self aligning carrying idler includes pivoting mechanisms to guide the belt under heavy loads. It’s used on the conveyor’s load-bearing side. This design prevents belt drift during material transport.

Q: When should a self aligning return idler be used?

A: A self aligning return idler is installed on the non-load-bearing (return) side of the conveyor. It maintains belt alignment during empty runs. This prevents edge damage and extends belt life.

Q: What industries benefit most from self aligning idlers?

A: Mining, quarrying, and bulk material handling industries rely on self aligning idlers. They excel in high-capacity, long-distance conveyor systems. Harsh environments with uneven loads see the greatest benefits.

Q: How often should self aligning idlers be maintained?

A: Inspect self aligning idlers every 3-6 months for debris and wear. Lubricate pivot points during routine maintenance. Replace components showing significant corrosion or deformation promptly.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025