Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Essential Components and Structures for Conveyor Frame Assembly and Maintenance Techniques

Understanding Conveyor Frame Parts An Essential Component in Material Handling Systems

In the modern industrial landscape, efficient material handling is critical for the smooth operation of manufacturing and distribution processes. At the heart of these systems lies the conveyor, an indispensable tool designed to facilitate the movement of goods across various manufacturing and logistical stages. Central to the functionality of a conveyor system is its frame, which serves as the backbone supporting the entire structure and its operations. This article delves into the significance of conveyor frame parts, their design, materials, and roles within a conveyor system.

The Structure of Conveyor Frames

Conveyor frames are typically constructed from robust and durable materials to provide stability and support. The most common materials used in the construction of conveyor frames include steel, aluminum, and plastic. Steel frames are often preferred for heavy-duty applications due to their strength and load-bearing capacity. On the other hand, aluminum frames are lightweight and corrosion-resistant, making them suitable for environments where weight reduction and mobility are essential. Plastic frames, while less common, can serve specific applications where chemical resistance or hygienic properties are necessary.

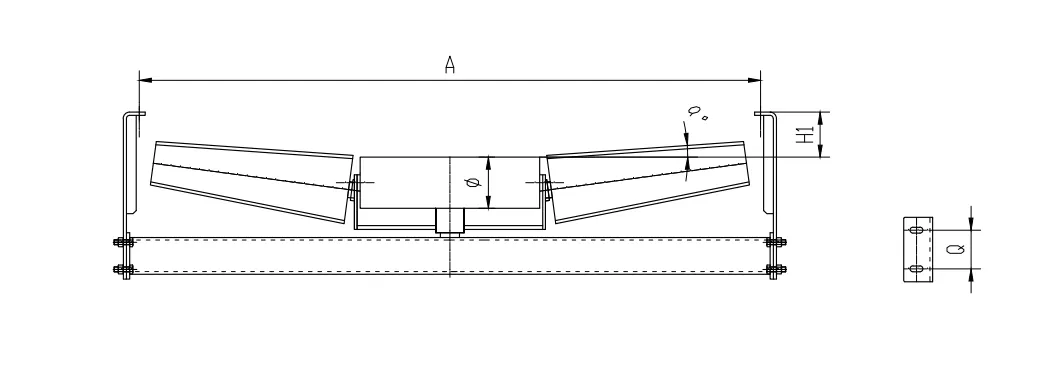

The frame itself consists of various components, each serving a distinct purpose. The main elements include side rails, cross beams, legs, and mounting brackets. Side rails form the outer edges of the conveyor, providing a pathway for items being transported while preventing them from falling off. Cross beams serve to connect the side rails, ensuring structural integrity and distributing the load evenly. The legs elevate the conveyor to an appropriate height, allowing ease of access and integration with other equipment. Mounting brackets are used to secure the conveyor frame to the ground or other machinery, enhancing stability during operation.

Importance of Frame Design

conveyor frame parts

The design of conveyor frame parts is crucial for the overall performance and efficiency of the conveyor system. A well-engineered frame will minimize maintenance requirements, reduce downtime, and enhance the reliability of the material handling process. Factors such as load capacity, alignment, and adjustability must be considered during the design phase.

For instance, load capacity is a vital consideration; frames must be designed to support not only the weight of goods being transported but also to withstand the dynamic forces generated during operation. Additionally, frames should be easily adjustable to accommodate various conveyor belt widths and lengths, providing flexibility in handling different products.

Customization and Modularity

One of the strengths of conveyor frames lies in their customizable and modular nature. Many modern conveyor systems are designed to be adaptable and scalable, allowing businesses to modify their material handling solutions as needs change. By utilizing modular frame parts, companies can create a system that perfectly aligns with their specific operational requirements, whether it involves expanding warehouse capabilities or implementing new production lines.

Conclusion

In summary, conveyor frame parts are a critical aspect of material handling systems, providing the necessary support and structure for efficient operation. Understanding their design, materials, and functional roles is essential for businesses looking to optimize their conveyor systems. By investing in high-quality and well-designed frame components, industries can enhance productivity, reduce operational costs, and ultimately, improve their overall efficiency. As technology advances and the demand for streamlined processes grows, the importance of these integral parts in the conveyor ecosystem will only continue to rise.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025