Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt parts and functions

Conveyor Belt Parts and Functions

Conveyor belts are an essential component of many industrial processes, serving as a means to transport materials from one location to another efficiently. Understanding the various parts of a conveyor belt and their specific functions is crucial for optimizing its operation, enhancing productivity, and ensuring safety in the workplace. This article will explore the primary components of conveyor belts and their roles in the system.

1. Belt

The belt itself is the most recognizable part of a conveyor system. Made from materials such as rubber, plastic, metal, or fabric, it acts as the medium through which materials are transported. The choice of belt material depends on the type of material being conveyed, the environment in which the system operates, and the desired lifespan of the belt. For example, rubber belts are commonly used in heavy-duty applications due to their durability, while lighter plastic belts might be used for lightweight packaging.

2. Pulley

Pulleys play a crucial role in the operation of conveyor belts. They are wheel-like structures that guide the belt and transfer power through rotation. There are generally two types of pulleys drive pulleys and idler pulleys. The drive pulley, connected to the motor, is responsible for moving the belt. The idler pulleys support the belt and maintain its tension throughout the conveyor system. Proper alignment and maintenance of the pulleys are critical to ensure smooth and efficient operation.

3. Motor

The motor is the powerhouse of the conveyor system, providing the necessary energy to move the belt. Depending on the application, different types of motors can be used, including AC motors, DC motors, and gear motors. The size and power of the motor depend on the weight and speed of the material being moved. Selecting the correct motor is vital for achieving optimal performance and minimizing the risk of mechanical failures.

4. Framework

conveyor belt parts and functions

The framework is what holds the entire conveyor system together. Typically made from steel or aluminum, it provides the necessary support and stability for the belt and other components. The design of the framework must ensure that it can withstand the weight of the materials being transported while maintaining the structural integrity throughout the conveyor's operation. Adjustable frameworks allow for modifications in height and angle, accommodating various transportation needs.

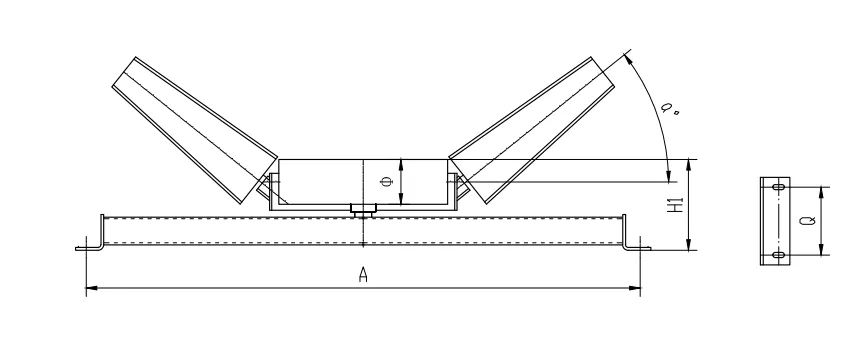

5. Guide Rollers

Guide rollers are supplementary components installed along the conveyor belt to maintain its alignment and prevent it from drifting off track. These rollers guide the belt along its intended path, reducing wear and tear and improving overall efficiency. Proper placement of guide rollers is essential, especially in curves and inclines, where the belt is more prone to misalignment.

6. Tensioning Device

The tensioning device keeps the belt taut, preventing slippage and ensuring optimal performance. Its primary function is to adjust the tension of the belt as it wears or stretches over time. Without proper tension, the belt may sag or slip off the pulleys, leading to disruptions in the conveyor system. Tensioning devices can be mechanical or automatic, depending on the system's design and requirements.

7. Safety Guards and Sensors

Safety is paramount in any industrial setting. Conveyor belts are equipped with safety guards and sensors to mitigate risks. Safety guards help protect workers from moving parts, while sensors can detect issues such as belt misalignment or jams. These safety features play a crucial role in maintaining a safe working environment and ensuring the conveyor system operates smoothly.

Conclusion

Understanding the various parts of a conveyor belt and their functions is essential for anyone working in an industrial setting. Each component plays a significant role in ensuring that materials are transported efficiently and safely. By maintaining and optimizing these parts, companies can enhance productivity, reduce downtime, and create a safer work environment. Proper knowledge and management of conveyor belt systems lead to improved operational effectiveness, making it a backbone of modern manufacturing and logistics.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025