Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

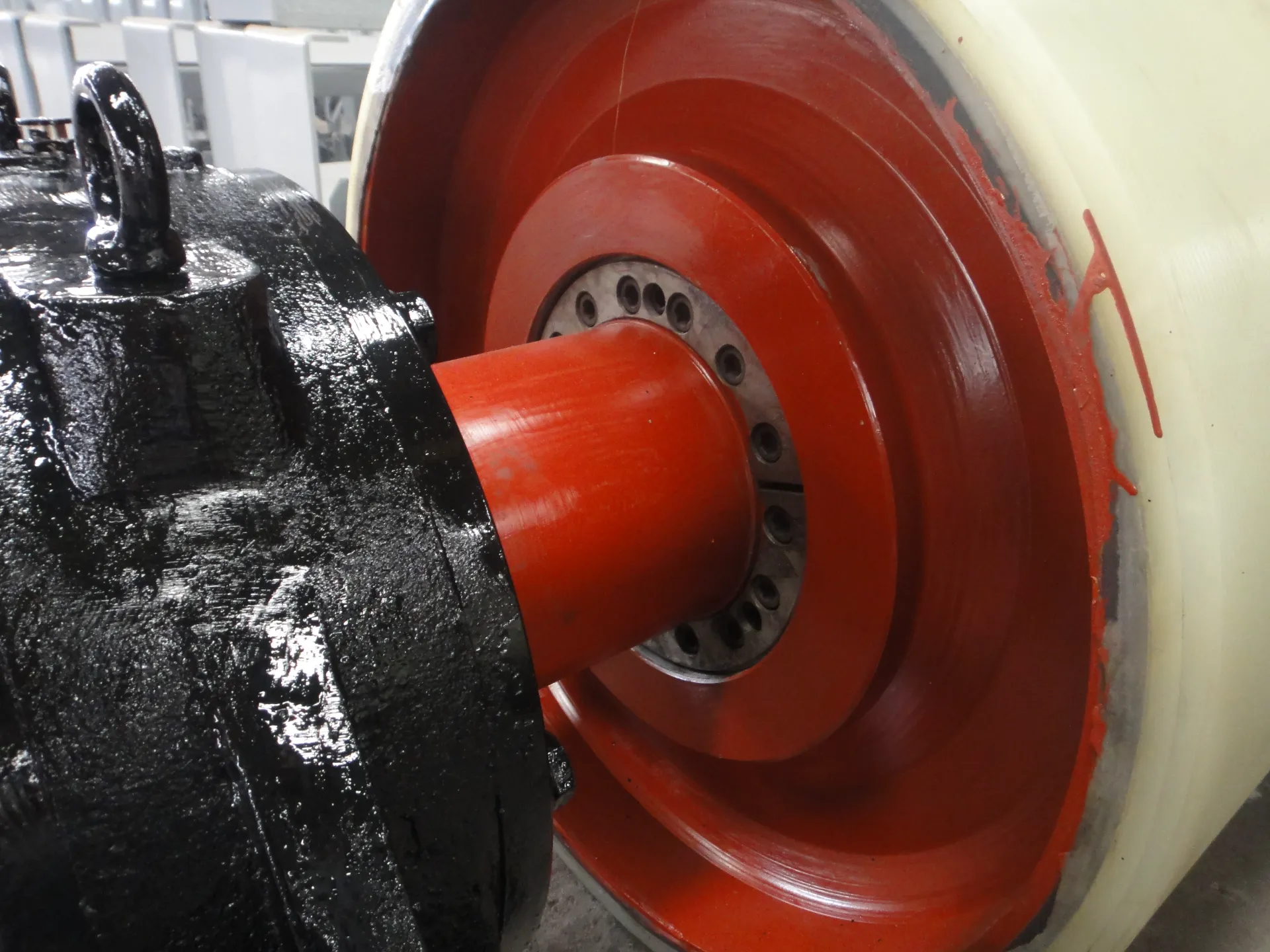

Zulu conveyor roller bracket

Understanding Conveyor Roller Brackets Essential Components for Efficient Material Handling

Conveyor systems have become a backbone in many industries, from manufacturing to logistics, allowing for efficient movement and transportation of materials. One critical component of these conveyor systems is the conveyor roller bracket. Understanding what these brackets are and their importance can enhance the effectiveness of any conveyor system.

What is a Conveyor Roller Bracket?

A conveyor roller bracket is a mechanical component that supports and holds conveyor rollers in place within a conveyor system. These brackets are essential for ensuring that rollers operate smoothly and are properly aligned, allowing for uninterrupted movement of materials. Typically made from durable materials such as steel or aluminum, conveyor roller brackets are designed to withstand the rigors of various industrial environments, including heavy loads, vibrations, and exposure to different materials.

The Role of Conveyor Roller Brackets

The primary function of conveyor roller brackets is to provide stability and support to the rollers. Rollers are the rotating components that facilitate the movement of materials along the conveyor belt. When rollers are secured properly with brackets, it ensures that there is minimal friction, which allows for smoother operation and less wear and tear on both the rollers and the conveyor belt.

Moreover, conveyor roller brackets play a significant role in the alignment of rollers. Proper alignment minimizes the chance of belt misalignment, which can lead to jams or malfunctions within the conveyor system. Misalignment can also cause uneven wear on the belt and rollers, eventually leading to costly repairs or replacements.

Types of Conveyor Roller Brackets

Conveyor roller brackets come in various designs, depending on the specific requirements of the conveyor system. Some common types include

conveyor roller bracket

1. Fixed Brackets These brackets are permanently attached to the conveyor frame and provide a stable base for the rollers. They are commonly used in applications where the angle and height of the conveyor do not change.

2. Adjustable Brackets These allow for customization of the roller height and angle, making them suitable for applications where the layout may change or require flexibility.

3. Support Brackets These are used to provide additional support for heavy-duty rollers, ensuring that they can handle substantial loads without flexing or bending.

4. End Brackets Positioned at the ends of the conveyor, these brackets help to secure the rollers and provide the necessary support to facilitate the entry and exit of materials.

Importance in Material Handling

The efficiency of a conveyor system directly impacts productivity in any industrial setting. By utilizing high-quality conveyor roller brackets, businesses can ensure that their conveyor systems run smoothly, reducing downtime caused by mechanical failures. Furthermore, the longevity of the entire system can be extended, saving companies money in the long term.

Regular maintenance of roller brackets is crucial. Companies should routinely inspect these brackets for any signs of wear or damage, as a compromised bracket can lead to larger issues within the conveyor system. This proactive approach helps in addressing potential problems before they escalate, ensuring continuous operation and maximizing efficiency.

Conclusion

In summary, conveyor roller brackets are vital components that ensure the stability and efficiency of conveyor systems. By understanding their function and importance, industries can better appreciate how these small yet significant parts contribute to the smooth operation of material handling processes. Investing in high-quality conveyor roller brackets and committing to their regular maintenance is essential for any business looking to optimize its operations and maintain a competitive edge in the ever-evolving industrial landscape. Through proper selection and care of these components, companies can enhance their productivity and reduce operational costs effectively.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025