Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 20:28

Back to list

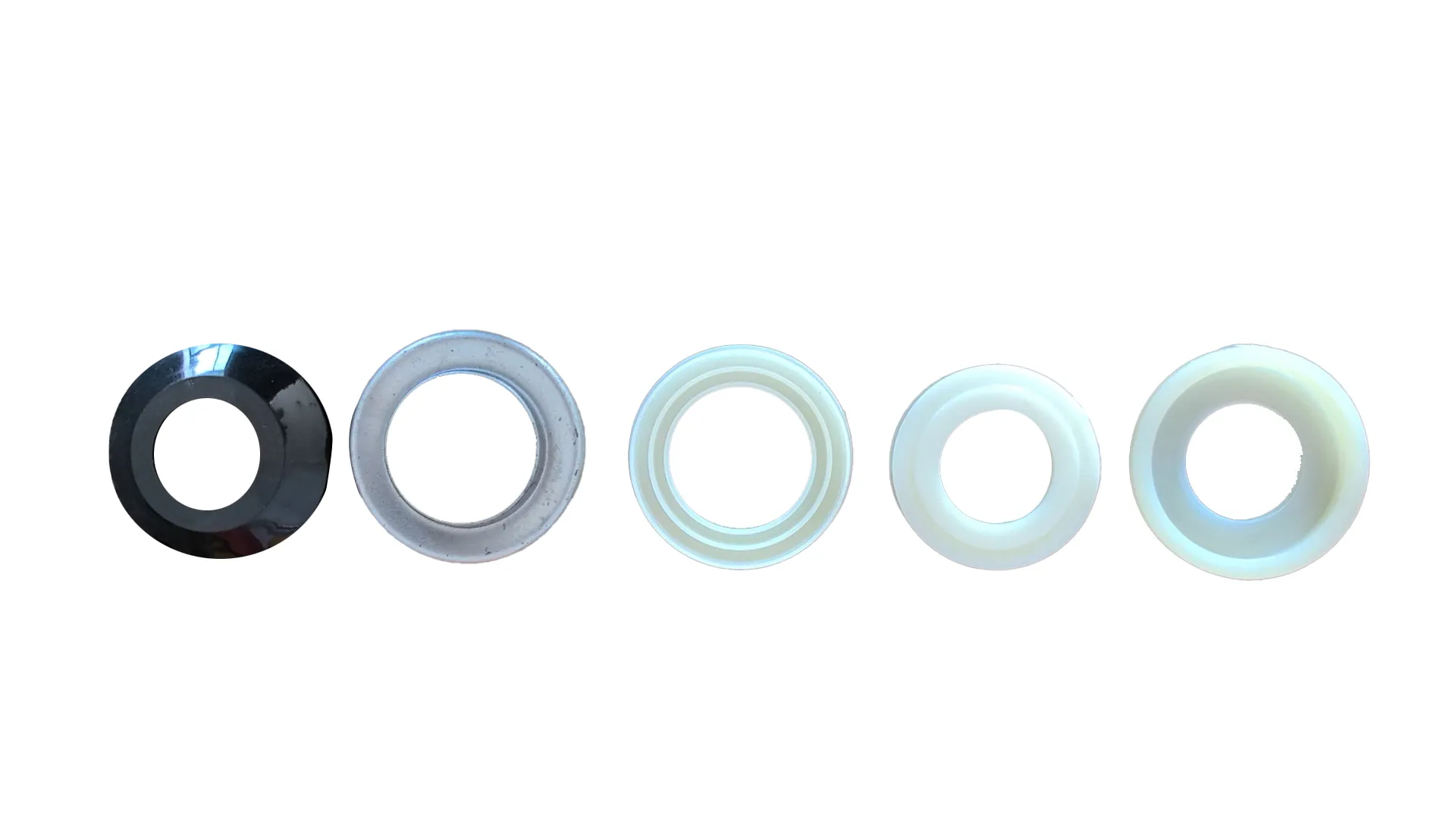

TR Seal

In the field of industrial engineering and manufacturing, the precision of seals and gaskets plays a crucial role in the efficiency and reliability of machinery. Among these critical components, the TR seal has emerged as a groundbreaking product, revolutionizing various sectors with its unique properties and applications. Drawing upon years of industry expertise, this article explores the multifaceted advantages of TR seals, showcasing why they are considered a benchmark in sealing technology.

Another key dimension of TR seal's appeal lies in their ease of installation and maintenance. Their sophisticated design does not compromise user-friendliness; they can be effortlessly integrated into existing systems, without necessitating extensive modifications to machinery. This user-centric design translates to lower installation costs and shorter downtimes, further driving their popularity among engineers and technicians globally. The credibility and authoritativeness associated with TR seals are also reflected in the accolades and certifications they have garnered from renowned industry bodies. These endorsements serve as a testament to their unmatched quality and reliability, reinforcing their position as a trusted choice in the market. Organizations that incorporate TR seals into their operations benefit from improved longevity and reduced risk of seal failure, fostering an environment of trust and confidence in their mechanical applications. Finally, adopting TR seals signifies a commitment to environmental responsibility, an increasingly crucial consideration for modern industries. The longevity and durability of these seals contribute to a reduction in material waste and lower energy consumption due to less frequent replacement and maintenance requirements. By choosing TR seals, companies are better positioned to meet sustainability targets and enhance their environmental credentials. In conclusion, TR seals epitomize the pinnacle of sealing technology, drawing upon extensive engineering expertise to deliver unmatched performance, reliability, and sustainability. With their proven track record across multiple industries, these seals are not just components— they are a strategic investment in operational excellence. As industries continue to evolve with more complex and demanding challenges, TR seals stand as a symbol of trust and innovation, underscoring their indispensable role in the world of industrial engineering.

Another key dimension of TR seal's appeal lies in their ease of installation and maintenance. Their sophisticated design does not compromise user-friendliness; they can be effortlessly integrated into existing systems, without necessitating extensive modifications to machinery. This user-centric design translates to lower installation costs and shorter downtimes, further driving their popularity among engineers and technicians globally. The credibility and authoritativeness associated with TR seals are also reflected in the accolades and certifications they have garnered from renowned industry bodies. These endorsements serve as a testament to their unmatched quality and reliability, reinforcing their position as a trusted choice in the market. Organizations that incorporate TR seals into their operations benefit from improved longevity and reduced risk of seal failure, fostering an environment of trust and confidence in their mechanical applications. Finally, adopting TR seals signifies a commitment to environmental responsibility, an increasingly crucial consideration for modern industries. The longevity and durability of these seals contribute to a reduction in material waste and lower energy consumption due to less frequent replacement and maintenance requirements. By choosing TR seals, companies are better positioned to meet sustainability targets and enhance their environmental credentials. In conclusion, TR seals epitomize the pinnacle of sealing technology, drawing upon extensive engineering expertise to deliver unmatched performance, reliability, and sustainability. With their proven track record across multiple industries, these seals are not just components— they are a strategic investment in operational excellence. As industries continue to evolve with more complex and demanding challenges, TR seals stand as a symbol of trust and innovation, underscoring their indispensable role in the world of industrial engineering.

Next:

Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS