Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Improving Efficiency with Troughing Rolls in Material Handling Systems

Understanding Troughing Rolls A Key Component in Conveyor Systems

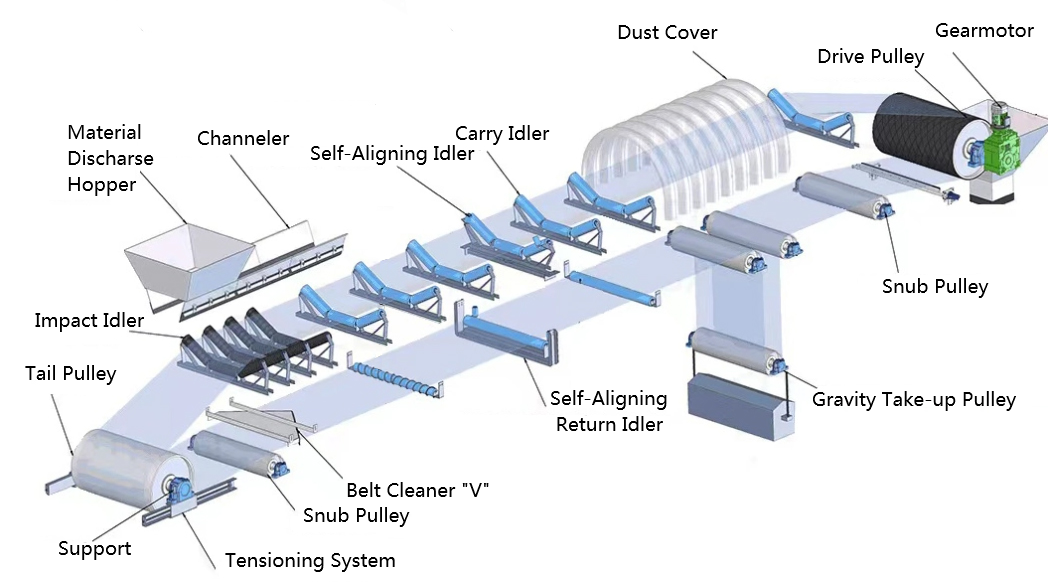

Troughing rolls are integral components in the design and function of conveyor systems, which are widely used in various industries including mining, agriculture, and material handling. These rolls are essential for supporting the conveyor belt as it moves material from one location to another, and play a critical role in ensuring the efficiency and reliability of the entire conveyor system.

What Are Troughing Rolls?

Troughing rolls are cylindrical rollers fixed on a conveyor support frame, specifically designed to carry and shape a conveyor belt into a trough-like profile. This design enables the transport of loose bulk materials, such as coal, grains, or minerals, minimizing spillage and maximizing load capacity. Troughing rolls are typically assembled in sets, with various angles of inclination—commonly 20°, 35°, or 45°—to create a trough that conforms to the material being transported.

The Importance of Troughing Rolls

The functionality of troughing rolls is multi-faceted. First and foremost, by bending the conveyor belt into a trough shape, they effectively contain materials, preventing them from falling off during transport. This containment is crucial for ensuring that the material reaches its destination without significant losses, which could lead to economic inefficiencies.

Additionally, troughing rolls facilitate easier movement of materials up inclines. The increased surface contact with the belt enhances friction, which in turn reduces the amount of energy required to move materials. This energy efficiency contributes to the overall operational cost savings, making conveyor systems more economically viable for businesses.

Design and Materials

Troughing rolls are engineered to withstand significant wear and tear. They are commonly made from robust materials such as steel, which provides durability and reliability. Some rolls feature rubber or other traction-enhancing coatings that improve grip and reduce slippage, especially in applications where moisture or other slippery substances are present.

troughing rolls

The design of troughing rolls can also be customized based on specific operational requirements

. Variations include adjusting the diameter of the rolls, configuring the frame for different types of installations, or using specialized bearings to handle heavier loads. These modifications ensure that the rolls can handle various materials and conditions effectively.Maintenance Considerations

For troughing rolls to function optimally, regular maintenance is essential. Routine inspections should focus on checking the alignment and condition of the rolls, as misalignment can lead to uneven wear on the conveyor belt and subsequent operational failures. The bearings should also be lubricated periodically to prevent friction and avoid premature wear.

Furthermore, while troughing rolls are designed for durability, they are not immune to damage. Encounters with foreign objects, improper loading, or even environmental factors can lead to breakage or deformation. Prompt identification and replacement of damaged rolls are critical to maintain the system's efficiency.

Innovations in Troughing Rolls

As technology continues to evolve, so do the designs and functionalities of troughing rolls. Innovations now include the incorporation of sensors and IoT technology that can provide real-time data about the operational state of the rolls and the conveyor system as a whole. This data-driven approach allows for predictive maintenance, which can significantly reduce downtime and maintenance costs.

Another advancement is the development of lightweight materials that maintain strength while reducing the overall weight of the rolls. This is particularly useful in applications where reducing the energy required for operation is a priority.

Conclusion

Troughing rolls are much more than simple components of a conveyor system; they represent a critical intersection of engineering and functionality that keeps industries running smoothly. Understanding the importance of these rolls, along with their design, maintenance, and potential innovations, underscores their role in enhancing the efficiency and effectiveness of material handling processes. As industries continue to advance, so too will the technologies surrounding troughing rolls, paving the way for even more efficient operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025