Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Inggris

Inggris  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

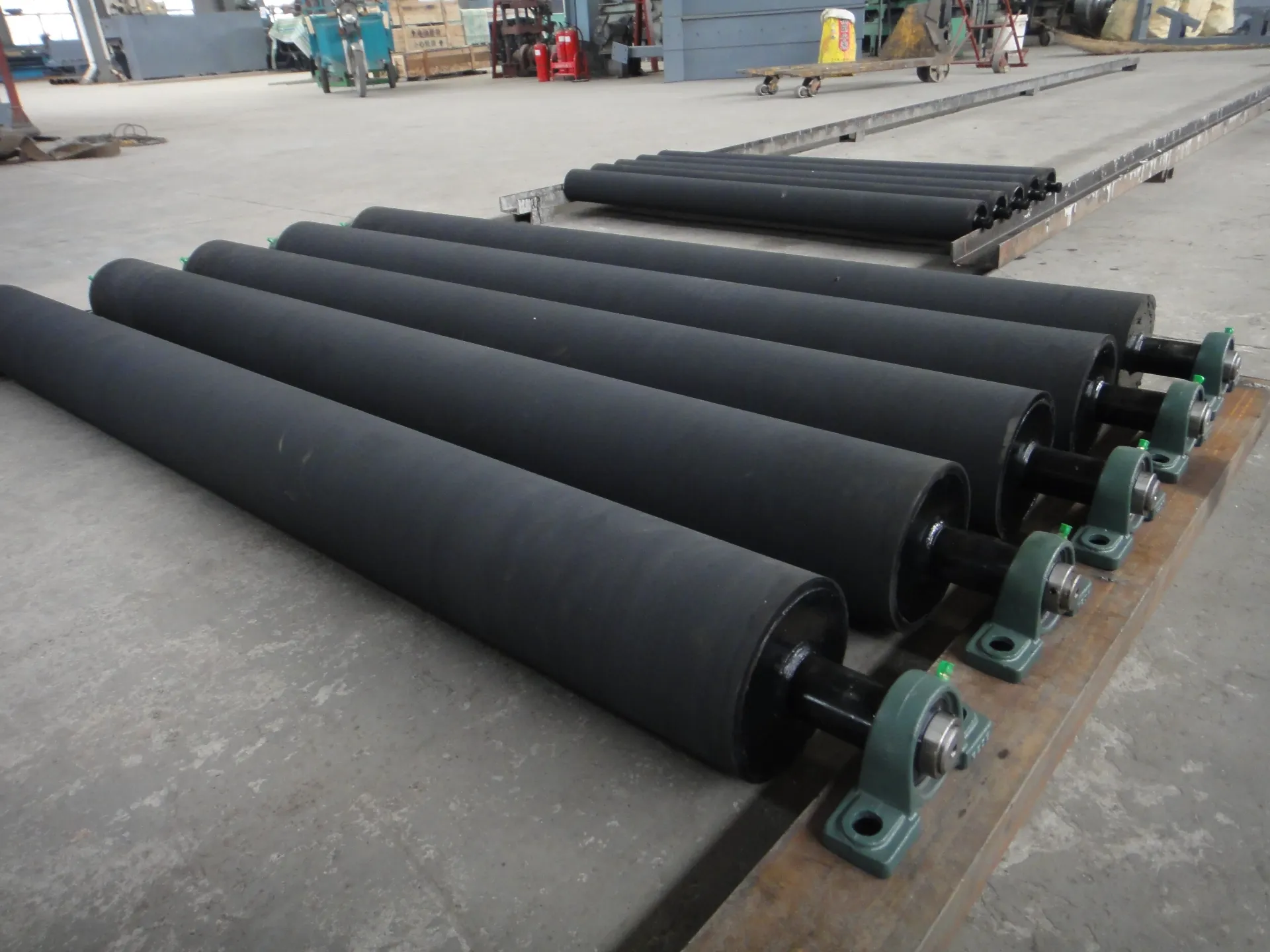

Zulu Smart Rubber Idler Rollers

In modern conveyor systems, self cleaning sleeve rubber disc idler rollers have become a standout component. These rollers are specially designed to automatically remove stuck materials on the return side of the belt, reducing downtime and maintenance. Thanks to their durable rubber disc sleeves, they maintain cleaner belt surfaces without extra labor. Their self-cleaning function is ideal for industries dealing with sticky or moist materials like coal, sand, or minerals. Their practical use has led to widespread popularity across different sectors, making them a go-to solution for improving conveyor belt efficiency and cleanliness.

Belt Conveyor Flat Idler Solutions for Everyday Use

A belt conveyor flat idler is the unsung hero of many bulk material transport systems. Found in almost every industrial setup, these flat idlers keep conveyor belts running smoothly and aligned. Their simple design belies their critical function: ensuring the load is carried evenly and preventing belt sag. These idlers are engineered to reduce resistance and extend belt life, proving indispensable in plants, factories, and warehouses. Their reliability and ease of replacement make them a smart, cost-effective investment for daily operations. As demand rises for energy-efficient systems, the flat idler remains a trusted part of sustainable conveyor setups.

Lower Flat Idler Performance in Dusty Workspaces

The lower flat idler is specifically installed on the return path of belt conveyors and plays a critical role in preventing belt misalignment. Especially useful in dusty, gritty environments, this idler keeps things moving efficiently even in challenging conditions. By supporting the return side of the belt, it reduces friction and prevents wear. The lower position also means it's often exposed to falling material and debris, making its toughness essential. Upgrading to a reliable lower flat idler helps extend the entire system’s service life. Its contribution, though often overlooked, can significantly reduce operational breakdowns in busy industrial areas.

Rubber Disc Return Rollers for Safer Conveyor Systems

Rubber disc return rollers are increasingly becoming a safety-first choice in conveyor systems. Designed with tough rubber rings spaced along the roller, they handle the dirty work of clearing carryback material off the belt. This not only improves belt tracking but also reduces the risk of material buildup and belt damage. These rollers offer a stable return path, especially helpful in systems where belts run long distances and carry heavy loads. Their rugged build resists wear from rough materials and their vibration-dampening quality leads to smoother operations. Many industries now prefer rubber disc return rollers to improve both performance and safety.

Lower Flat Idler and Rubber Disc Return Rollers Combo

Combining lower flat idler units with rubber disc return rollers creates a robust and efficient conveyor solution for high-volume operations. The flat idler handles the return path evenly, while the disc roller actively manages debris. Together, they offer longer belt life, lower noise levels, and reduced maintenance costs. This combo ensures that belts stay aligned and free from damaging material build-up. It’s particularly effective in mining, agriculture, and construction industries where downtime is costly. Investing in this combination is a smart move for operations aiming for higher productivity with minimal maintenance needs.

Self Cleaning Sleeve Rubber Disc Idler FAQs

What materials can the self cleaning sleeve rubber disc idler handle best?

The self cleaning sleeve rubber disc idler is best suited for sticky and moist materials like coal, wet sand, and clay, as it prevents them from sticking to the return side of the conveyor belt.

How long does a belt conveyor flat idler typically last?

With proper installation and maintenance, a belt conveyor flat idler can last several years, depending on workload and environmental conditions.

Is the lower flat idler hard to install or replace?

No, the lower flat idler is straightforward to install or replace, especially in standard conveyor systems, and usually doesn’t require specialized tools.

Do rubber disc return rollers need frequent maintenance?

Rubber disc return rollers require less maintenance than traditional rollers because their self-cleaning discs prevent material buildup, reducing wear and tear.

Can I combine multiple roller types in one system?

Yes, combining different roller types like lower flat idlers and rubber disc return rollers often improves system efficiency and reduces maintenance across the board.

Now is the perfect time to upgrade your conveyor system with high-performance self cleaning sleeve rubber disc idler and rubber disc return rollers. These tools are already enhancing operations across industries and could do the same for yours. Visit our website today to explore full product details, request a quote, or speak with our support team. Don’t wait—smarter, smoother conveying starts with the right rollers.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersKabarJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsKabarJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingKabarJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingKabarJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingKabarJun.27,2025

-

Enhancing Material Handling EfficiencyKabarJun.27,2025