Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Efficient Solutions for Maintaining Conveyor Systems and Ensuring Optimal Cleaning Practices

The Importance of Conveyor Cleaner Systems in Modern Industries

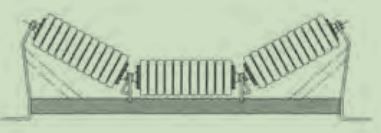

Conveyor systems are integral to the functioning of various industries, including manufacturing, mining, and food processing. These systems facilitate the efficient movement of materials, ensuring that production processes run smoothly. However, the continuous operation of conveyor belts can lead to the accumulation of debris, dust, and other contaminants. This is where conveyor cleaners come into play, playing a vital role in maintaining hygiene, efficiency, and longevity of the equipment.

Conveyor cleaners are devices specifically designed to remove unwanted materials from conveyor belts. They vary in design and complexity from simple brush systems to high-tech automated cleaning solutions. The primary goal of these cleaners is to ensure that the conveyor belts operate effectively without obstructions that might hinder the movement of materials. By keeping the belts clean, industries can improve their overall productivity, reduce the likelihood of equipment failure, and ensure product quality.

One of the major benefits of using conveyor cleaners is the enhancement of safety in the workplace. A clean conveyor belt significantly reduces the risk of slipping and falling hazards caused by spills or accumulated materials. This is particularly crucial in industries like food processing, where the presence of contaminants can not only damage equipment but also lead to health risks for employees and consumers alike. By integrating effective cleaning systems, companies can foster a safer working environment while complying with health and safety regulations.

conveyor cleaner

In terms of efficiency, conveyor cleaners contribute to the seamless operation of industrial processes. When a conveyor belt is clean, it minimizes friction and wear on both the belt and the carrying equipment. This leads to reduced energy consumption and prolongs the lifespan of the machinery. Furthermore, regular cleaning helps in maintaining the throughput rate of the conveyor systems, ensuring that production targets are met without unnecessary delays. Companies that invest in efficient cleaning systems often see a return on investment through increased operational efficiency and reduced downtime.

Another significant aspect of conveyor cleaners is their role in maintaining product quality. In industries such as food processing, even a small amount of contamination can lead to defective products or, in the worst case, foodborne illnesses. Conveyor cleaners help to eliminate dust, debris, and residues that may interfere with the integrity of the products being transported. By ensuring that conveyor systems are free from contaminants, companies can guarantee consistent product quality, which is a key factor in consumer satisfaction and brand loyalty.

The advancement of technology has also seen the evolution of conveyor cleaning systems. Modern conveyor cleaners can be equipped with sensors and automation features that allow for real-time monitoring and cleaning. These systems can adjust their cleaning intensity based on the type and amount of material being transported, leading to optimized cleaning performance. Moreover, the integration of smart technology enables predictive maintenance, which alerts operators about potential issues before they lead to costly breakdowns.

In conclusion, conveyor cleaners are indispensable tools in maintaining the efficiency, safety, and quality standards of industrial operations. They facilitate the smooth functioning of conveyor systems by keeping them free from contaminants while also promoting a safe working environment. As industries continue to evolve and demand higher efficiencies, the importance of adopting advanced conveyor cleaning solutions will only grow. Investing in suitable cleaning systems is not just about compliance; it is a strategic move that can significantly enhance operational performance and ultimately contribute to the success of a business.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025