Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Effective Conveyor Solutions with High-Performance Carrying Rollers for Efficient Material Handling Systems

The Importance of Conveyor Carrying Rollers in Material Handling Systems

In the modern industrial landscape, efficiency and reliability are key components of successful logistics and material handling systems. One pivotal element in these systems is the conveyor carrying roller. These rollers play an essential role in transporting a wide range of materials, from heavy machinery parts to lightweight packages, across various industries.

What Are Conveyor Carrying Rollers?

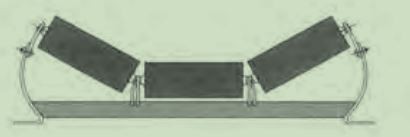

Conveyor carrying rollers are cylindrical components that support and guide the conveyor belts used in material handling systems. They are typically made from durable materials such as steel, aluminum, or plastic, designed to withstand the weight and impact of the material being transported. These rollers are positioned beneath the conveyor belt and serve multiple purposes, including load support, facilitating movement, and reducing friction.

How Do Conveyor Carrying Rollers Work?

The primary function of carrying rollers is to provide a stable surface for the conveyor belt to roll over. When materials are placed on the conveyor belt, the weight is evenly distributed across the rollers. This design minimizes wear and tear on the belt while ensuring that the materials are moved smoothly and efficiently. As the conveyor belt moves, the carrying rollers rotate, providing the necessary movement to transport goods from one point to another.

Moreover, the use of carrying rollers contributes significantly to reducing operational costs. By minimizing the friction between the belt and the rollers, these components help to decrease energy consumption, making the entire system more efficient. This efficiency not only leads to lower utility bills but also extends the lifespan of both the conveyor belt and the carrying rollers themselves.

conveyor carrying roller

Types of Conveyor Carrying Rollers

There are several types of conveyor carrying rollers, each suited for specific applications. For instance, plain rollers, which have a smooth surface, are commonly employed for general-purpose conveying tasks. In contrast, rubber-coated rollers can provide additional grip and are advantageous in applications where slipping might occur.

Another variant is the troughing roller, which has a groove design that creates a U shape. This design is particularly useful for transporting bulk materials like grains or powders, as it helps to contain the load and prevent spillage. Additionally, there are also impact rollers designed to absorb shocks during the loading of heavy materials, thus protecting the conveyor system from damage.

Maintenance of Conveyor Carrying Rollers

To ensure the longevity and functionality of conveyor carrying rollers, regular maintenance is crucial. This typically involves inspecting the rollers for wear and tear, cleaning them to prevent the buildup of debris, and lubricating the bearings for smooth operation. Implementing a proactive maintenance schedule can prevent costly downtimes and repairs, keeping the material handling systems operating at peak performance.

Conclusion

Conveyor carrying rollers are indispensable components in the material handling industry, enhancing the efficiency and effectiveness of transporting materials. Their design not only aids in load support and movement but also contributes to the overall sustainability of operations by reducing energy consumption. As industries continue to evolve towards more automated and efficient processes, the role of conveyor carrying rollers will remain vital. Companies that invest in high-quality rollers and regular maintenance will likely see increased productivity and reduced operational costs, highlighting the importance of these seemingly simple devices in the complex world of material handling.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025