Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Ògmh . 25, 2024 02:44

Back to list

Smooth Roller Guides Essential Techniques for Efficient Motion Control

The Pivotal Role of Roller Guides in Precision Engineering and Manufacturing

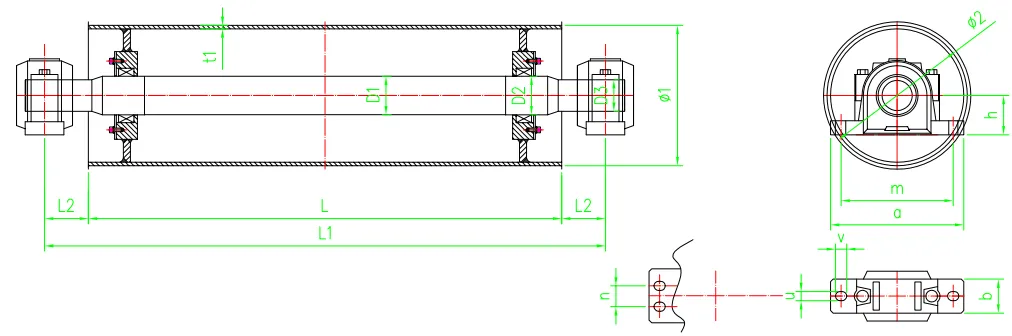

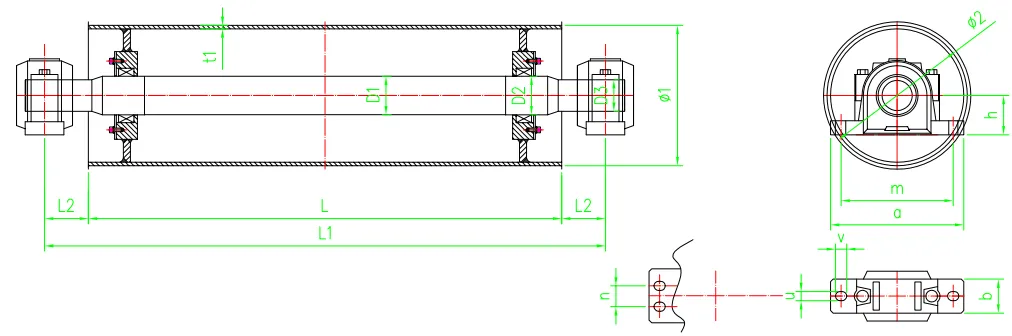

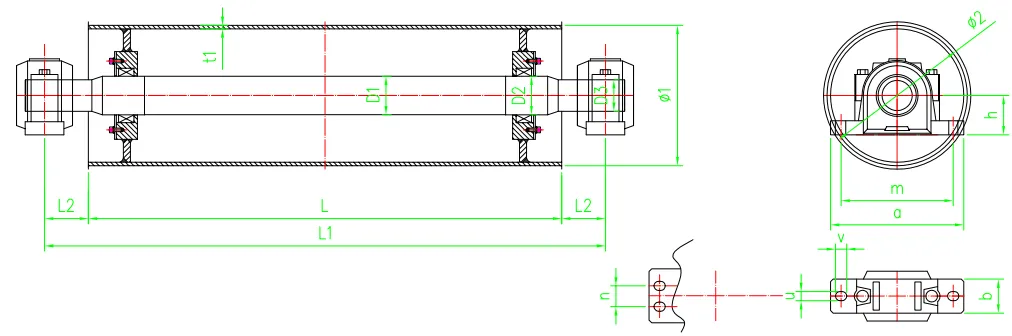

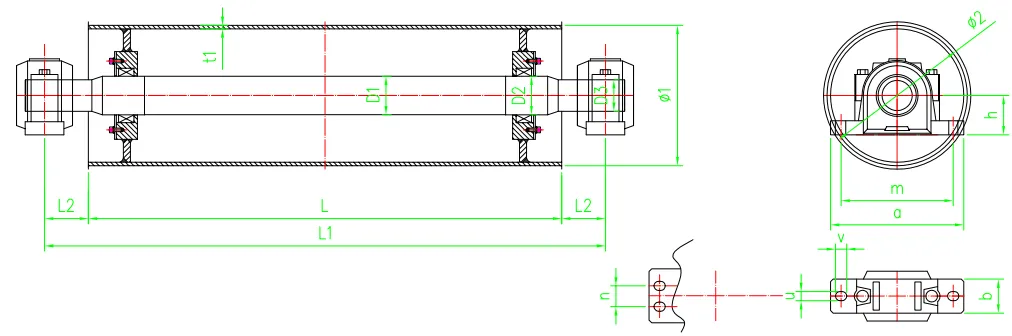

In the intricate dance of modern industrial machinery, roller guides hold a position of paramount importance. Often referred to as the silent guardians of smooth operation, they function as the backbone of precision systems, ensuring that components move with unparalleled accuracy and efficiency. Roller guides, essentially, are elements of linear motion control, found in a myriad of applications from assembly lines to robotics.

At their core, roller guides consist of rollers that ride on a track or rail, guiding the movement of heavy or delicate objects with minimal friction. Their design is meticulously crafted to minimize wear and tear, while maintaining stability and rigidity, crucial for maintaining consistent performance over time. These guides can be made from various materials, including steel, plastic, or even composite materials, each chosen for specific durability and load-bearing capacity.

One of the key benefits of roller guides is their ability to provide high levels of repeatability and precision. In manufacturing environments where accuracy is a must, such as in semiconductor fabrication or medical device production, the slightest deviation can lead to costly errors. Roller guides ensure that parts travel along their intended path with an astonishing level of consistency, thus enhancing product quality and reducing wastage.

Moreover, roller guides are known for their low maintenance requirements. Unlike other moving parts that may require lubrication or periodic adjustments, these systems often operate self-contained, needing minimal intervention. This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process

This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process roller guides.

In the realm of automation, roller guides play a pivotal role in the integration of conveyors and robotic arms. They facilitate seamless transitions between different stages of production, enabling efficient material flow and reducing bottlenecks. By facilitating precise positioning and alignment, roller guides contribute to the overall productivity and competitiveness of automated systems.

However, advancements in technology have led to the development of smart roller guides, equipped with sensors and monitoring systems. These intelligent devices can detect and report any anomalies, allowing for early intervention and predictive maintenance. This not only prolongs the life of the equipment but also enhances safety by preventing potential accidents.

In conclusion, roller guides are an indispensable component in the world of engineering and manufacturing. Their ability to maintain precision, reduce friction, and facilitate automation has revolutionized the way we design and operate complex machinery. As technology continues to evolve, roller guides will undoubtedly adapt and evolve, further enhancing the efficiency and reliability of modern industrial processes.

roller guides.

In the realm of automation, roller guides play a pivotal role in the integration of conveyors and robotic arms. They facilitate seamless transitions between different stages of production, enabling efficient material flow and reducing bottlenecks. By facilitating precise positioning and alignment, roller guides contribute to the overall productivity and competitiveness of automated systems.

However, advancements in technology have led to the development of smart roller guides, equipped with sensors and monitoring systems. These intelligent devices can detect and report any anomalies, allowing for early intervention and predictive maintenance. This not only prolongs the life of the equipment but also enhances safety by preventing potential accidents.

In conclusion, roller guides are an indispensable component in the world of engineering and manufacturing. Their ability to maintain precision, reduce friction, and facilitate automation has revolutionized the way we design and operate complex machinery. As technology continues to evolve, roller guides will undoubtedly adapt and evolve, further enhancing the efficiency and reliability of modern industrial processes.

This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process

This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process This not only saves time and labor but also contributes to a cleaner and more sustainable manufacturing process roller guides.

In the realm of automation, roller guides play a pivotal role in the integration of conveyors and robotic arms. They facilitate seamless transitions between different stages of production, enabling efficient material flow and reducing bottlenecks. By facilitating precise positioning and alignment, roller guides contribute to the overall productivity and competitiveness of automated systems.

However, advancements in technology have led to the development of smart roller guides, equipped with sensors and monitoring systems. These intelligent devices can detect and report any anomalies, allowing for early intervention and predictive maintenance. This not only prolongs the life of the equipment but also enhances safety by preventing potential accidents.

In conclusion, roller guides are an indispensable component in the world of engineering and manufacturing. Their ability to maintain precision, reduce friction, and facilitate automation has revolutionized the way we design and operate complex machinery. As technology continues to evolve, roller guides will undoubtedly adapt and evolve, further enhancing the efficiency and reliability of modern industrial processes.

roller guides.

In the realm of automation, roller guides play a pivotal role in the integration of conveyors and robotic arms. They facilitate seamless transitions between different stages of production, enabling efficient material flow and reducing bottlenecks. By facilitating precise positioning and alignment, roller guides contribute to the overall productivity and competitiveness of automated systems.

However, advancements in technology have led to the development of smart roller guides, equipped with sensors and monitoring systems. These intelligent devices can detect and report any anomalies, allowing for early intervention and predictive maintenance. This not only prolongs the life of the equipment but also enhances safety by preventing potential accidents.

In conclusion, roller guides are an indispensable component in the world of engineering and manufacturing. Their ability to maintain precision, reduce friction, and facilitate automation has revolutionized the way we design and operate complex machinery. As technology continues to evolve, roller guides will undoubtedly adapt and evolve, further enhancing the efficiency and reliability of modern industrial processes. Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS