Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu mining conveyor rollers

The Importance of Mining Conveyor Rollers in Modern Mining Operations

Mining operations are at the heart of many industries, supplying essential raw materials such as coal, metal ores, and minerals that fuel construction, energy, and manufacturing. Within these operations, the efficiency of material handling plays a crucial role in determining overall productivity and cost-effectiveness. One of the key components of material handling in mining is the conveyor system, specifically conveyor rollers. This article explores the significance of mining conveyor rollers, their types, and their impact on mining processes.

Conveyor rollers are cylindrical devices that facilitate the movement of materials along a conveyor system. They are positioned at intervals along the conveyor belt to support and guide it, allowing for the smooth transport of bulk materials across various distances and terrains. Given the harsh operating conditions in mining environments, these rollers must be built to withstand significant stress, abrasive materials, and varying loads.

There are several types of mining conveyor rollers, each designed for specific applications. The most common types include

1. Idler Rollers These are the most frequently used rollers in conveyor systems. Idler rollers support the weight of the conveyor belt and the material being transported. They come in various design configurations—such as troughing idlers, which have a slight inclination to enhance material containment and prevent spillage.

2. Return Rollers Located on the underside of the conveyor belt, return rollers help to guide the belt back to its starting point. Their role is crucial in ensuring that the conveyor belt maintains its alignment and prevents any sagging or misalignment that could lead to excessive wear.

mining conveyor rollers

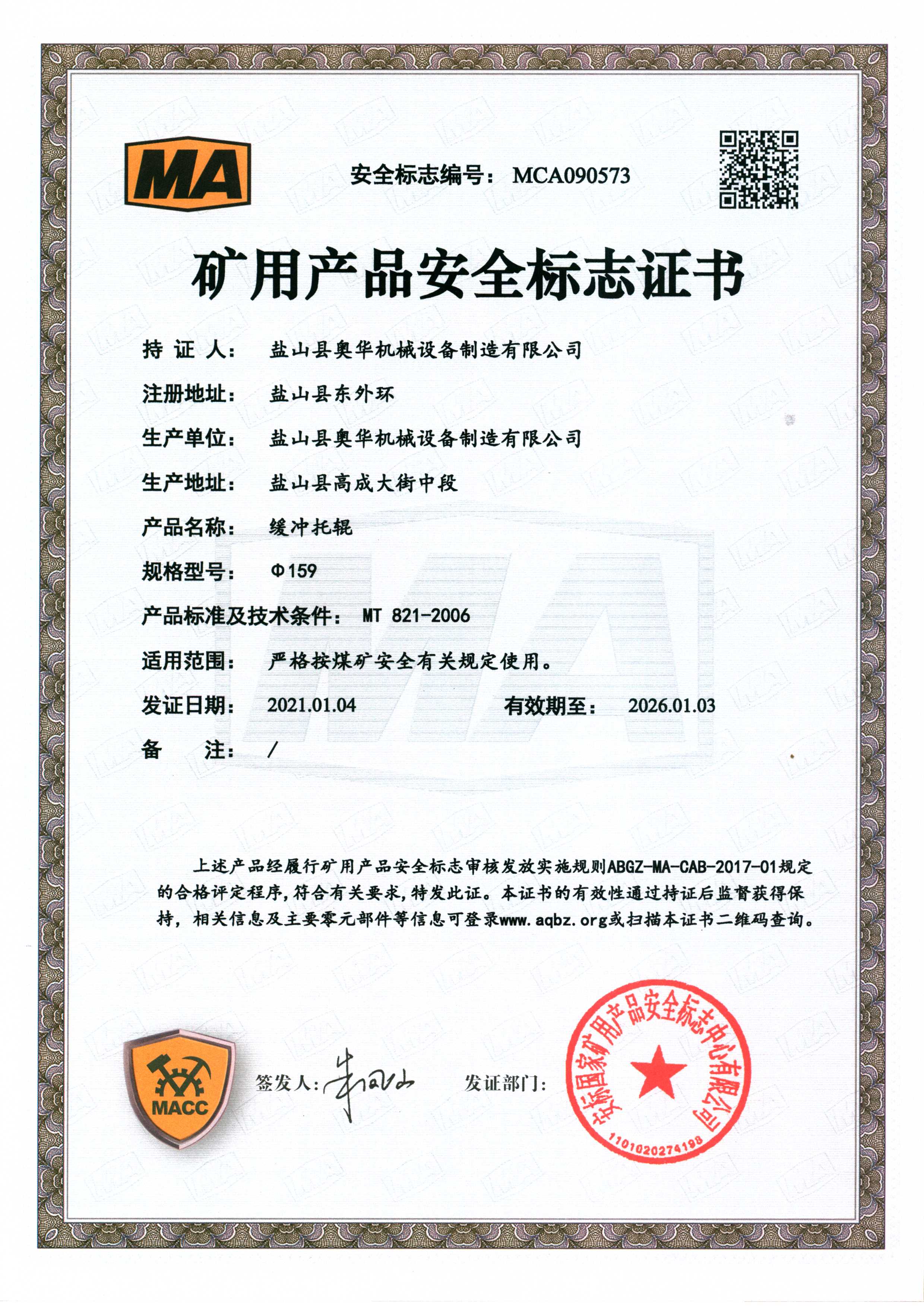

3. Impact Rollers Placed at key points along the conveyor, impact rollers are designed to absorb shock loads from heavy materials being discharged onto the belt. They play an essential role in protecting the conveyor system from damage due to sudden impacts.

4. Self-Cleaning Rollers These innovative rollers are designed to reduce the build-up of materials on the conveyor system, thereby improving efficiency. Self-cleaning rollers prevent spillage and material accumulation, which can cause belt tracking issues and additional wear.

The material composition of conveyor rollers is another critical factor impacting their performance and lifespan. Most rollers are manufactured from high-quality steel or durable polymers that can resist corrosion, wear, and tear. The choice of material is influenced by the specific mining environment and the type of materials being transported.

In modern mining operations, optimizing the efficiency of conveyor systems can lead to significant cost savings and increased productivity. Improved conveyor roller technology has led to better energy efficiency, reduced maintenance requirements, and longer service life. The implementation of advanced materials and engineering designs enables mining companies to transport heavier loads over longer distances with minimal energy consumption.

Moreover, with the integration of automation and digital technologies, conveyor systems can now be monitored in real-time. This capability allows for predictive maintenance, ensuring that any potential issues with conveyor rollers are addressed proactively. By using data analytics and sensors, mining operators can minimize downtime and extend the lifespan of their equipment.

In conclusion, mining conveyor rollers are vital components of efficient material handling in the mining industry. Their ability to support, guide, and protect conveyor belts ensures smooth operations and contributes to the overall productivity of mining activities. As technology continues to advance, the role of conveyor rollers will only become more critical in meeting the increasing demands for efficiency and sustainability in the mining sector. By investing in high-quality rollers and embracing modern maintenance practices, mining operations can enhance their competitiveness and ensure long-term success.