Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt rollers for sale

Conveyor Belt Rollers for Sale A Comprehensive Guide

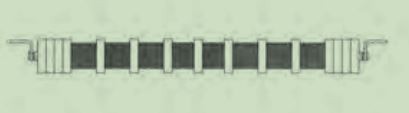

Conveyor belt rollers play an essential role in various industries, facilitating the smooth transport of goods and materials. These rollers are critical components of conveyor systems, designed to support the conveyor belt and assist with the movement of items along the production line. In this article, we will explore the different types of conveyor belt rollers available for sale, their features, applications, and important factors to consider before making a purchase.

Types of Conveyor Belt Rollers

1. Idler Rollers Idler rollers are used to support the conveyor belt and maintain its tension. They play a crucial role in ensuring that the belt runs smoothly along the conveyor frame. Common material options for idler rollers include steel, plastic, and rubber, with each type offering its own advantages in terms of durability and resistance to wear and tear.

2. Drive Rollers As the name suggests, drive rollers are responsible for moving the conveyor belt. They are connected to a power source that enables them to rotate and drive the belt forward. Drive rollers can be found in various configurations, such as lagged, crowned, or flat, depending on the specific application requirements.

3. Return Rollers Return rollers are used to support the conveyor belt as it returns to its starting position. They help to keep the belt aligned and prevent sagging, ensuring a more efficient operation. These rollers are commonly designed to minimize friction and wear, thus prolonging the lifespan of the conveyor system.

4. Impact Rollers Used in areas where heavy loads are transferred onto the conveyor belt, impact rollers are specifically designed to absorb shock and reduce the risk of damage. These rollers often feature heavy-duty construction and additional cushioning to protect both the conveyor system and the transported materials.

5. Specialty Rollers Beyond the standard types, there are also specialty rollers that cater to specific needs. For example, rollers designed for food processing machinery may meet strict hygiene standards, while rollers engineered for dusty environments might incorporate sealed bearings to reduce maintenance needs.

Features to Consider

conveyor belt rollers for sale

When searching for conveyor belt rollers for sale, several features are essential to consider

- Material The choice of material impacts the roller’s strength, weight, and resistance to environmental factors. Steel rollers are robust and suitable for heavy-duty applications, while plastic rollers may be more lightweight and resistant to corrosion.

- Size and Dimensions Rollers come in various sizes, and it's critical to choose ones that match the specifications of your conveyor system. Measure the width, diameter, and length required for your application to ensure a proper fit.

- Load Capacity Consider the weight of the materials you’ll be transporting. Each roller type has a different load capacity, and exceeding this limit can lead to premature failure.

- Bearing Type The type of bearings used in the rollers can affect their performance and maintenance requirements. Sealed bearings are ideal for environments with dust or moisture, as they require less frequent lubrication.

Where to Buy Conveyor Belt Rollers

There are numerous suppliers and manufacturers offering conveyor belt rollers for sale. It's important to consider purchasing from reputable dealers who provide high-quality products. Online marketplaces, industrial supply stores, and specialized manufacturers are all great options. Be sure to compare prices, warranty options, and customer reviews to make an informed decision.

Conclusion

Investing in the right conveyor belt rollers is vital for the efficiency and productivity of your operations. By understanding the different types of rollers available, their features, and the applications suited for each, you can select the best options for your needs. With the right equipment in place, you can ensure smooth transport processes, minimize downtime, and enhance the overall performance of your conveyor systems. Whether you are upgrading existing rollers or installing a new conveyor system, exploring the market for quality conveyor belt rollers will set you up for success in any industrial application.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025