Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Optimizing Conveyor Systems with Enhanced Head Roller Design for Improved Material Handling Efficiency

Understanding Conveyor Head Roller The Backbone of Material Handling Systems

In the world of material handling, efficiency and reliability are paramount. Conveyor systems have become an indispensable part of industries ranging from manufacturing to logistics, and central to these systems is the conveyor head roller. This component plays a critical role in the overall functioning of conveyor belts, influencing aspects like stability, performance, and maintenance.

What is a Conveyor Head Roller?

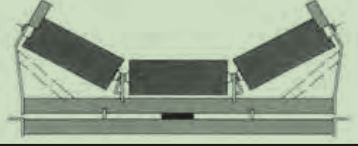

A conveyor head roller, or head pulley, is positioned at the discharge end of a conveyor belt. This roller serves multiple purposes, including guiding the conveyor belt, maintaining its tension, and facilitating the movement of materials. The design and functionality of the head roller are crucial for ensuring that material transfer is smooth and efficient.

Typically made of high-strength materials, such as steel or composite substances, the head roller is engineered to withstand significant operational stresses. It usually features a cylindrical shape, with a rubber or other form of surface that enhances friction, aiding in the movement of materials. During operation, the head roller drives the belt forward, allowing materials to be transported from one location to another.

Importance of Proper Head Roller Functionality

The head roller is integral to the success of any conveyor system. If the roller malfunctions or wears out, the entire system can be compromised. Potential issues include belt misalignment, which may cause material spillage, increased wear on the belt, and in severe cases, complete system failure. Regular maintenance of the head roller, including inspections and replacements, is essential to prevent such issues.

conveyor head roller

Moreover, a well-functioning head roller contributes to increased productivity. By ensuring that materials are effectively transferred without interruption, companies can achieve more efficient operations, ultimately leading to cost savings and better service delivery.

Design Variations

Head rollers come in various designs to meet the specific needs of different industries. For example, some rollers are designed with a crowned shape, helping to keep the belt centered and minimizing slippage. Others may have lagging – a surface treatment that improves grip and reduces wear on the belt. In environments where extreme conditions are the norm, such as mining or recycling, specialized head rollers are manufactured to handle heavy loads and abrasive materials.

Customization and Material Selection

The selection of materials for head rollers is also tailored to the application. For instance, industries that deal with corrosive substances might opt for stainless steel rollers to ensure longevity and resistance to rust. Additionally, in sectors requiring hygienic conditions, like food processing, non-porous and easy-to-clean materials may be preferred.

Conclusion

The conveyor head roller is often an underappreciated component of material handling systems, yet its significance cannot be overstated. From maintaining belt tension to enhancing efficiency, the head roller is vital for smooth operations. With continued advancements in technology and materials, the design and functionality of these rollers are continually improving, leading to more robust and reliable conveyor systems. Industries aiming to enhance their material handling processes must recognize the importance of investing in high-quality conveyor head rollers, ensuring optimal performance and longevity of their systems. Investing in the right head roller can lead not only to improved efficiency but also to substantial cost savings over the lifespan of the conveyor system.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025