Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Head and Tail Pulleys in Belt Conveyor Systems for Enhanced Performance

Head and Tail Pulleys for Belt Conveyors An Overview

Belt conveyors are essential systems in various industries, enabling the efficient transport of materials across diverse terrains. Two critical components of these conveyors are the head pulley and tail pulley. Understanding their functions and importance can enhance the effectiveness and longevity of belt conveyor systems.

The Role of Head Pulleys

The head pulley, located at the discharge end of the conveyor, plays a vital role in the system's operation. It is responsible for controlling the belt's movement and facilitating the transfer of materials from the conveyor onto another designated area. The head pulley typically has a higher diameter than the tail pulley to generate sufficient traction on the belt. This design ensures that the belt remains taut and properly aligned during operation.

Moreover, the head pulley is often equipped with additional features such as a conveyor drive mechanism. This feature can be either a direct motor drive or a pulley-driven assembly that enables the head pulley to rotate and, consequently, drive the belt forward. The ability to control the belt speed is crucial, as different materials may require different handling techniques.

In many applications, head pulleys are designed to be crowned. This means that they have a slight curve at the center, which helps to keep the belt centered and prevents it from drifting off to one side. Keeping the belt properly aligned not only enhances operational efficiency but also reduces wear and tear on both the belt and other components of the conveyor system.

The Importance of Tail Pulleys

On the other end of the conveyor lies the tail pulley, which serves a contrasting yet equally important function. The tail pulley is usually fixed and located at the loading end of the conveyor. Its primary purpose is to support the weight of the conveyor belt and to maintain tension. Without the proper tension in the belt, it could slip off the pulleys, leading to operational failures.

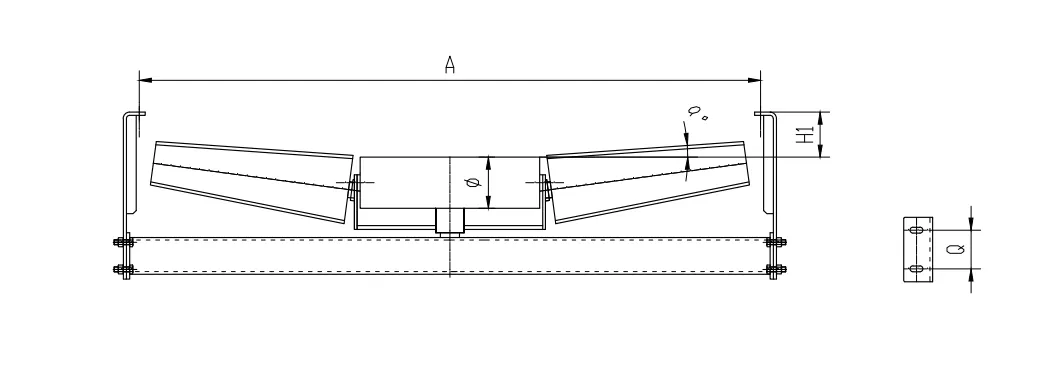

head pulley tail pulley for belt conveyor

Tail pulleys can also be equipped with tail guards that prevent material spillage. Given their location at the loading end, tail pulleys must endure significant stress and friction, often causing them to wear down over time. It is therefore essential to select tail pulleys made from durable materials that can withstand these harsh conditions. Just like head pulleys, tail pulleys may be fitted with other mechanical devices designed to help maintain proper belt tension.

While head pulleys focus on the movement and discharge of materials, tail pulleys are mainly about ensuring that the belt operates seamlessly and efficiently from the start of its journey. This balance between the two is what makes the belt conveyor system effective in achieving its material transport goals.

Maintenance and Longevity

Effective maintenance of both head and tail pulleys is crucial for the overall health of the belt conveyor system. Regular inspections should be conducted to check for signs of wear, alignment issues, or damage. Proper lubrication of bearings and regular tension checks can help prevent unforeseen breakdowns and prolong the life of the equipment.

In the case of a malfunction in either pulley, the entire conveyor system can experience a significant reduction in efficiency. Thus, it is advisable to employ predictive maintenance techniques, utilizing technology to monitor performance continuously. This proactive approach can help identify issues before they lead to significant downtime or costly repairs.

Conclusion

Head and tail pulleys are essential components of belt conveyor systems. They work together to ensure the efficient transport of materials while maintaining the integrity and functionality of the conveyor belt. Understanding their roles, and ensuring they are well-maintained, can result in enhanced operational efficiency and reduced wear over time. As industries continue to rely on belt conveyors for their material handling needs, the importance of these pulleys cannot be overstated. Choosing the right designs and materials for head and tail pulleys can significantly impact the productivity and reliability of conveyor systems across various applications.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025