Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring Various Types of Conveyor Rollers and Their Applications in Industry

Understanding Different Types of Conveyor Rollers

Conveyor rollers are essential components of material handling systems, enabling the efficient transport of goods in various environments, from manufacturing plants to warehouse facilities. Their design may vary based on the application, type of load, and specific operational requirements. In this article, we will explore the different types of conveyor rollers, their functions, and the applications in which they excel.

1. Steel Rollers

Steel rollers are among the most common types used in conveyor systems. Characterized by their robust construction, these rollers can bear heavy loads and withstand harsh environments. Steel rollers are often coated to resist corrosion and wear, making them suitable for applications involving heavy materials or where durability is paramount. They are widely used in industries such as mining, construction, and heavy manufacturing.

2. Plastic Rollers

Plastic rollers provide a lightweight alternative to steel, making them easier to handle and install. They are resistant to corrosion and chemicals, which makes them ideal for applications in food processing, pharmaceuticals, and packaging. Plastic rollers minimize noise and reduce friction, enhancing the efficiency of the conveyor system while ensuring a smoother operation. Additionally, they are often used in lighter-duty applications where weight and flexibility are essential.

3. Rubber Coated Rollers

These rollers are designed with a rubber coating to provide enhanced grip and reduce slippage during the transporting of goods. The rubber surface can absorb shock and vibrations, helping to protect fragile loads. Rubber coated rollers are particularly useful in applications where the materials being conveyed need to be handled carefully, such as in the automotive industry or when moving finished goods.

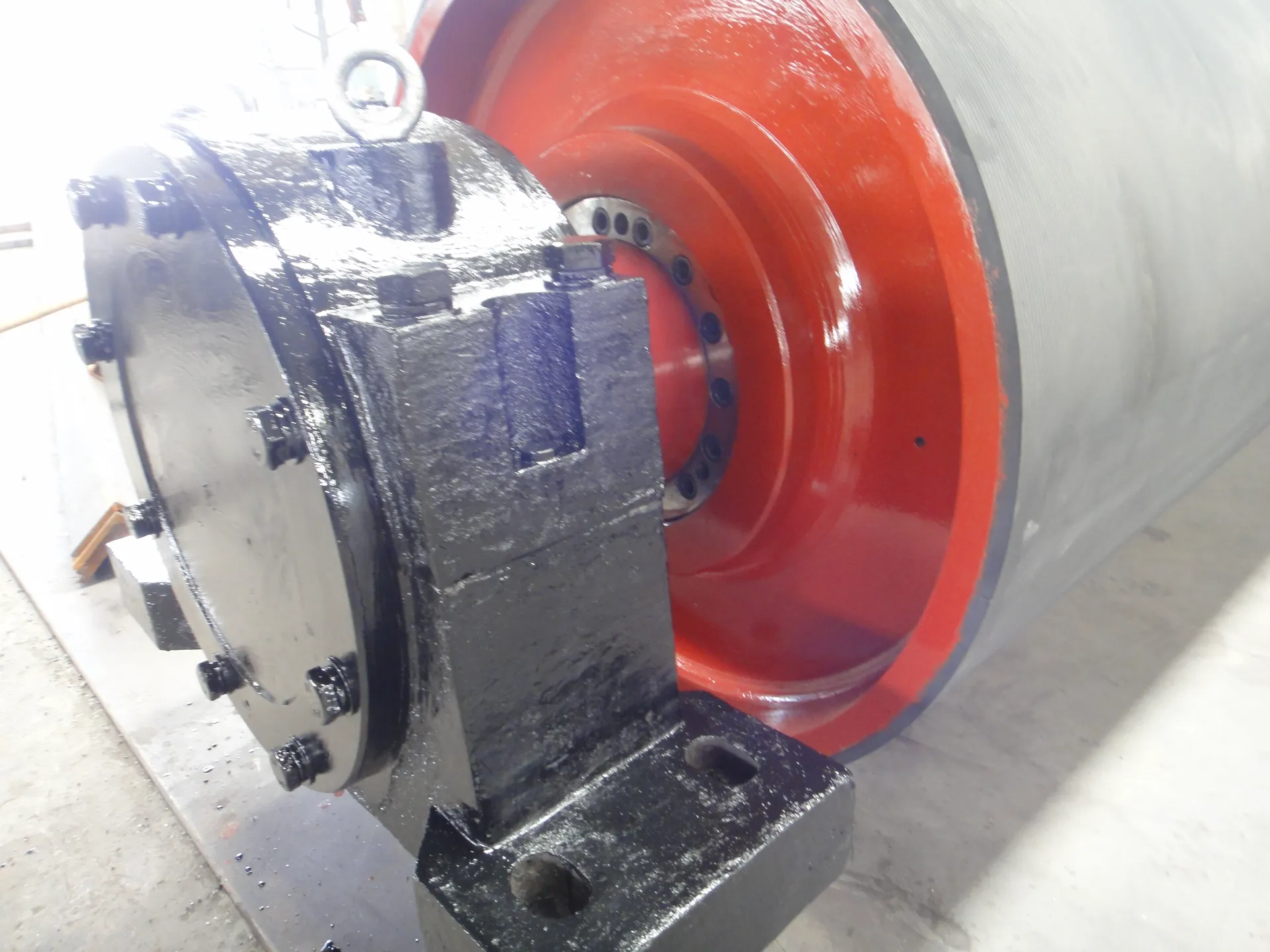

different types of conveyor rollers

Gravity rollers operate based on the principle of gravity and are often used in applications requiring a simple, low-cost solution for material handling. They are typically installed at a slight incline, allowing products to roll from one end to the other. Gravity roller conveyors are common in distribution centers and assembly lines, where they facilitate the movement of products without the need for powered systems.

5. Powered Rollers

Unlike gravity rollers, powered rollers use a motor to drive them, making them suitable for handling heavier loads or products that require controlled speeds. Powered rollers are typically found in high-capacity systems where automation is a key focus. They are ideal for sorting and merging applications, particularly in warehouses and shipping facilities where precise handling of packages is critical.

6. Specialty Rollers

Specialty rollers are designed for specific applications and can include features like tapering for better alignment, or roller beds designed to handle unique products such as tires or irregularly shaped items. Examples include high-friction rollers used for incline applications and rollers designed for use in temperature-controlled environments, such as freezer applications in the food industry.

7. Custom Rollers

Many manufacturers now offer custom solutions tailored to the unique needs of a business. Custom conveyor rollers can be made from various materials, with different lengths, diameters, and coatings, ensuring that they meet specific operational demands. This option is increasingly popular among companies looking to optimize their material handling processes, as it provides flexibility and a tailored approach.

Conclusion

Understanding the different types of conveyor rollers is crucial for businesses looking to optimize their material handling systems. Selecting the right roller can significantly impact the efficiency and effectiveness of loading and unloading operations. Whether it’s heavy-duty steel rollers for robust industrial processes or lightweight plastic rollers for gentle handling of fragile goods, each type serves a critical purpose. By carefully considering the material, application, and load requirements, businesses can streamline their processes, reduce downtime, and improve overall productivity. As technology continues to evolve, the development of new roller types and materials will further enhance the functionality of conveyor systems, making them an indispensable part of modern logistics and manufacturing.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025