Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor roller mounting brackets

Understanding Conveyor Roller Mounting Brackets Importance and Applications

Conveyor systems play a crucial role in various industries, facilitating the efficient movement of goods and materials. At the heart of these systems are conveyor rollers, which are essential components that support and transport products along the conveyor belt. However, the functionality of these rollers largely depends on the effectiveness of the conveyor roller mounting brackets. This article explores the significance of conveyor roller mounting brackets, their types, and their applications in various industries.

What are Conveyor Roller Mounting Brackets?

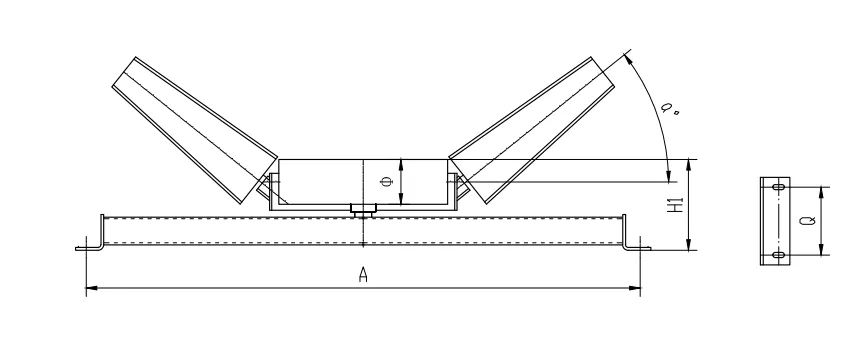

Conveyor roller mounting brackets are structural components that serve the purpose of securely holding conveyor rollers in place. These brackets are designed to provide stability, alignment, and easy maintenance of the rollers, ensuring that they operate smoothly and efficiently. The quality and design of these brackets can directly affect the performance of the entire conveyor system.

Importance of Conveyor Roller Mounting Brackets

1. Stability and Support Mounting brackets provide the necessary support for rollers, stabilizing them and preventing any undue movement or misalignment. This stability is vital for maintaining the overall structure of the conveyor system and ensuring operational reliability.

2. Ease of Maintenance Properly designed mounting brackets allow for easy access to the rollers, making maintenance tasks such as inspections, cleaning, and replacements more convenient. This can significantly reduce downtime and enhance the longevity of the conveyor system.

3. Load Distribution The brackets facilitate the even distribution of weight across the conveyor rollers. This is essential to prevent overloading, which can lead to premature wear and failure of both the rollers and the conveyor system.

4. Customization Conveyor roller mounting brackets can be tailored to meet specific operational needs. Different types of brackets are available to accommodate various roller sizes, materials, and mounting configurations, allowing businesses to optimize their conveyor systems.

Types of Conveyor Roller Mounting Brackets

Conveyor roller mounting brackets come in various types, each suited for different applications and environments. Some common types include

conveyor roller mounting brackets

2. End Cap Brackets These brackets fit over the ends of the rollers, providing end-to-end support. They are commonly used in applications requiring additional stability.

3. Adjustable Brackets Designed for flexibility, adjustable brackets allow for height and angle adjustments, accommodating changes in manufacturing processes or material handling needs.

4. Heavy-Duty Brackets For demanding environments, heavy-duty brackets are engineered to support high loads and withstand harsh conditions, such as those found in industrial settings.

Applications in Various Industries

Conveyor roller mounting brackets are utilized across a multitude of industries, including

- Manufacturing In production lines where products are continually moved, stable and reliable mounting brackets are essential for high efficiency.

- Logistics and Warehousing These brackets support conveyor systems that facilitate the movement of packages, ensuring that they are transported securely and efficiently.

- Food and Beverage In this sector, sanitation is paramount. Specialized mounting brackets allow for easy cleaning while maintaining the integrity of the conveyor system.

- Mining and Agriculture Heavy-duty brackets are crucial in these industries to handle the weight of bulk materials, ensuring safe and effective transport.

Conclusion

In summary, conveyor roller mounting brackets are indispensable components that contribute to the overall functionality and efficiency of conveyor systems across various industries. By providing stability, ease of maintenance, and customization options, these brackets play a pivotal role in enhancing the performance and longevity of conveyor systems. As technology advances and industries evolve, the development and application of innovative mounting bracket designs will continue to be essential for the future of material handling solutions.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025