Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu polyurethane idler rollers

The Importance of Polyurethane Idler Rollers in Modern Industry

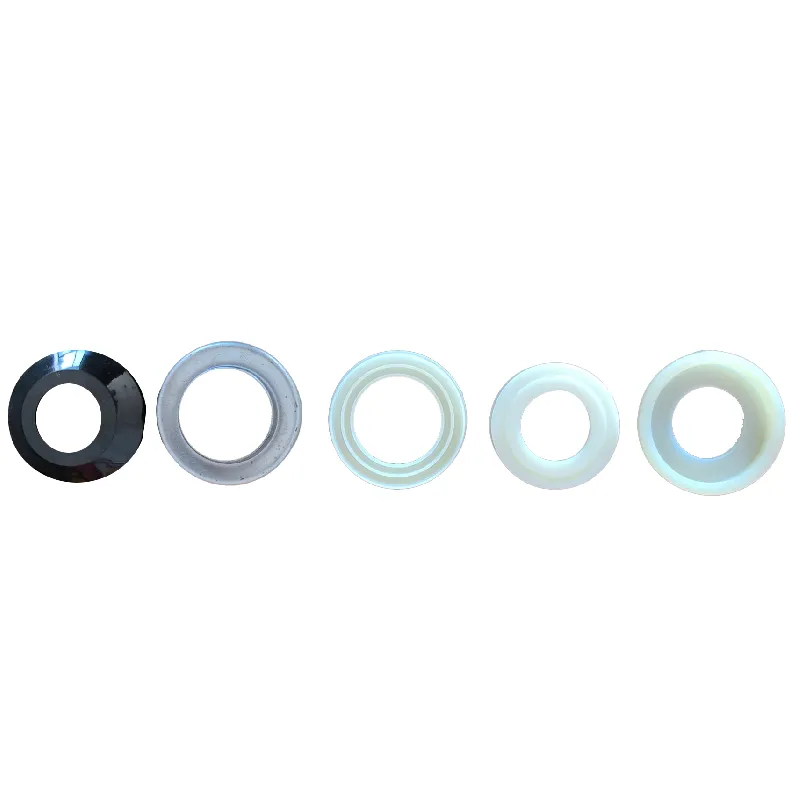

Polyurethane idler rollers have become integral components in various industrial applications due to their durability, flexibility, and resistance to wear and tear. These rollers are designed to facilitate the movement of materials in conveyor systems, enhancing efficiency and productivity across multiple sectors. In this article, we will explore the significance of polyurethane idler rollers, their properties, applications, and why they are preferred over traditional materials.

What are Polyurethane Idler Rollers?

Idler rollers are cylindrical components that reduce friction and support the movement of materials in a conveyor system. Unlike drive rollers, which actively move products, idler rollers passively guide materials along the conveyor path. Polyurethane, a versatile polymer, is used to coat or create these rollers, providing a robust surface that can withstand heavy loads and harsh operating conditions.

Properties of Polyurethane

The choice of polyurethane as a material for idler rollers is primarily due to its unique properties

1. Durability Polyurethane is known for its excellent wear resistance, which is essential in settings where rollers are subjected to constant friction and abrasion.

2. Flexibility This material can be engineered to achieve varying hardness levels, enabling the production of rollers that can adapt to different loads and applications.

3. Chemical Resistance Polyurethane exhibits resistance to oils, solvents, and chemicals, making it suitable for environments where exposure to such substances is common.

4. Noise Reduction The elastic properties of polyurethane help to dampen vibrations and noise, contributing to a quieter working environment.

5. Lightweight Compared to metal rollers, polyurethane rollers are considerably lighter, easing the burden on conveyor systems and reducing energy consumption.

Applications of Polyurethane Idler Rollers

Polyurethane idler rollers find applications across a wide range of industries

polyurethane idler rollers

2. Food Processing In food and beverage industries, the chemical resistance of polyurethane allows for safe transportation of various food products without contamination.

3. Mining In mining operations, the durability of polyurethane rollers is critical as they encounter harsh materials and heavy loads.

4. Textile Industry Polyurethane rollers are often used in textile processing where they assist in the movement of fabrics through various stages of production.

5. Packaging In packaging plants, idler rollers help move packaged goods smoothly through the conveyor systems, ensuring a continuous flow of products.

Advantages Over Traditional Materials

While traditional idler rollers are often made from materials such as rubber or steel, polyurethane rollers offer several advantages

1. Reduced Downtime The durability of polyurethane leads to less frequent replacements and maintenance, reducing overall operational downtime.

2. Cost-Effectiveness Although the initial investment might be higher, the longevity and reduced maintenance costs associated with polyurethane idler rollers make them a cost-effective choice in the long run.

3. Versatility Polyurethane rollers can be custom-made to meet specific requirements, such as size, hardness, and chemical resistance, allowing for application-specific solutions.

4. Energy Efficiency The lightweight nature of polyurethane reduces the energy required to operate conveyor systems, contributing to lower operational costs over time.

Conclusion

In conclusion, polyurethane idler rollers are crucial components in various industrial applications, offering significant advantages over traditional materials. Their durability, flexibility, and resistance to various environmental factors make them suitable for diverse settings, from food processing to heavy manufacturing. As industries continue to seek efficient and cost-effective solutions, the demand for polyurethane idler rollers is expected to grow, solidifying their place as a cornerstone in modern industrial operations. Investing in high-quality polyurethane idler rollers not only improves operational efficiency but also enhances the overall lifespan of conveyor systems, driving productivity into the future.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025