Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor roller assembly

Understanding Conveyor Roller Assembly An Essential Component in Material Handling

In today's fast-paced industrial landscape, efficiency and speed are paramount to maintaining a competitive edge. An often-overlooked but critical element in achieving these efficiencies is the conveyor roller assembly. This article explores the importance, components, and benefits of conveyor roller assemblies in material handling systems.

What is a Conveyor Roller Assembly?

A conveyor roller assembly is a fundamental part of a conveyor system responsible for facilitating the smooth movement of materials from one point to another. It typically consists of rollers mounted on frames that allow items to be transported with minimal friction. These assemblies are versatile and can be designed for various applications, including manufacturing, warehousing, and distribution.

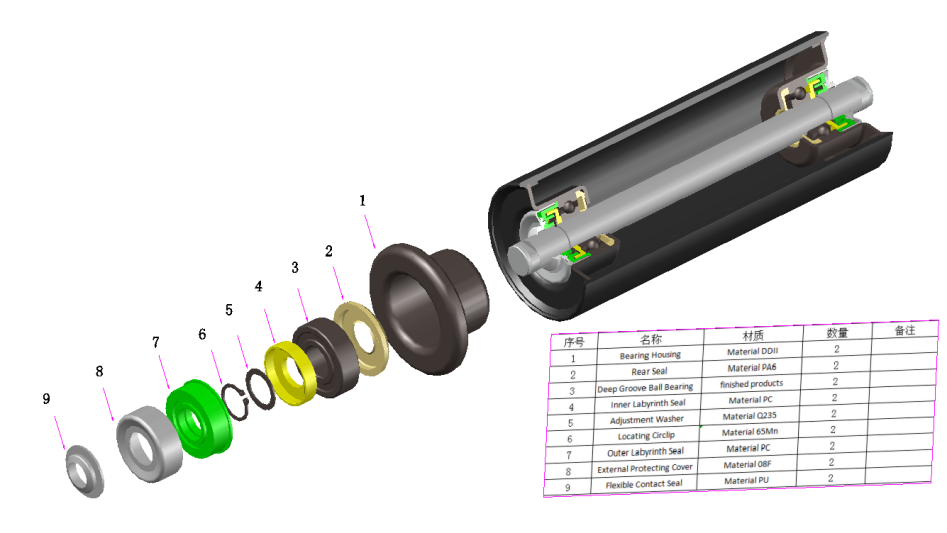

Key Components of a Conveyor Roller Assembly

1. Rollers The primary component of any conveyor roller assembly, rollers can be manufactured from various materials, including steel, plastic, and rubber, to suit specific use cases. They can be smooth or have a textured surface, depending on the type of products being moved.

2. Frames The frame provides structural support for the rollers and ensures proper alignment. Frames can be constructed from different materials, such as aluminum or steel, to offer strength and durability.

3. Bearings Bearings are vital for allowing the rollers to spin freely. High-quality bearings reduce friction and wear, which extends the lifespan of the conveyor system.

4. Mounting Brackets These components secure the roller assembly to the conveyor structure. Proper mounting is essential to keep the system stable and operational.

conveyor roller assembly

Benefits of Conveyor Roller Assemblies

Conveyor roller assemblies offer several benefits that contribute to the efficiency and effectiveness of material handling systems

1. Reduced Labor Costs By automating the transportation of goods, companies can minimize the need for manual handling, which leads to lower labor costs and increased productivity.

2. Increased Speed Conveyor roller assemblies allow for rapid movement of materials, reducing transit times and improving operational efficiency.

3. Versatility These assemblies can be configured to suit a wide range of materials and environments, making them ideal for diverse industries—from food processing to logistics.

4. Low Maintenance With durable components and efficient design, conveyor roller assemblies require less frequent maintenance compared to other material handling systems, saving on both time and costs.

5. Enhanced Safety By reducing the need for manual handling, conveyor roller assemblies also minimize the risk of workplace injuries, creating a safer work environment for employees.

Conclusion

The conveyor roller assembly is a pivotal component in modern material handling systems. Understanding its components and benefits is essential for optimizing operations and enhancing productivity. As industries continue to evolve, investing in high-quality conveyor roller assemblies will be crucial for companies seeking to improve their logistics and material handling processes. Embracing this technology not only makes for a more efficient workplace but also positions businesses for future growth and success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025