Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Assembly and Installation Guidelines for Conveyor Roller Systems in Material Handling Applications

Understanding Conveyor Roller Assembly An Essential Component in Material Handling

In the world of material handling systems, conveyor roller assemblies play a pivotal role in the efficient movement of goods across various industries. These assemblies facilitate streamlined operations in manufacturing, warehousing, and distribution, making them indispensable for any organization that relies on bulk material transportation. Understanding the anatomy, functionality, and benefits of conveyor roller assemblies can significantly enhance operational efficiency and productivity.

Anatomy of Conveyor Roller Assembly

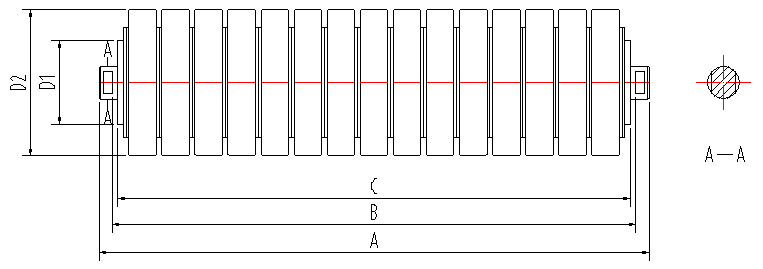

A conveyor roller assembly is composed of several key components that work in harmony to facilitate the smooth transportation of materials. The primary parts include the roller, frame, bearings, and drive mechanism.

1. Rollers The rollers are cylindrical components that directly support the materials being transported. They can be made from various materials, including steel, plastic, or rubber, depending on the application's specific requirements. The roller's diameter and width can also vary to accommodate different types of materials and loads.

2. Frame The frame serves as the backbone of the conveyor system. It provides structural integrity, supporting the rollers and the load being carried. Frames can be constructed from steel or aluminum and are designed for durability and resistance to wear and tear.

3. Bearings Bearings minimize friction between the rollers and frame, allowing for smooth rotation of the rollers. Proper bearing selection is critical, as it affects the efficiency and lifespan of the conveyor system.

4. Drive Mechanism The drive mechanism is responsible for powering the conveyor belt or roller system. It can include electric motors, gear systems, or other automated systems that provide the necessary torque to move materials effectively.

Functionality of Conveyor Roller Assembly

conveyor roller assembly

The primary function of the conveyor roller assembly is to facilitate the horizontal movement of materials from one point to another. The roller assembly acts as a support and drive system that allows payloads to glide smoothly without excessive manual handling. This automated process drastically reduces the potential for employee injury and minimizes the time spent on moving items.

Conveyor roller assemblies can be found in various configurations, including belt conveyors, gravity conveyors, and powered roller conveyors. Each system has its unique advantages depending on the application. For example, gravity conveyors employ rollers that rely on gravity for movement, making them an economically favorable choice for gentle material handling.

Benefits of Conveyor Roller Assembly

1. Increased Efficiency Conveyor systems equipped with roller assemblies are designed for optimal flow, which significantly increases the speed, efficiency, and dependability of material handling. This efficiency translates to faster production times and improved operational throughput.

2. Safety Manual handling poses risks for workers; conveyor roller assemblies reduce the need for heavy lifting, thereby minimizing the likelihood of workplace injuries. Furthermore, these systems can be equipped with safety features such as emergency stops and guards.

3. Versatility Conveyor roller assemblies can be customized to suit an array of applications across different industries, including logistics, mining, agriculture, and manufacturing. This versatility makes them an essential component of any material handling system.

4. Cost Savings While the initial investment in a conveyor roller assembly may seem substantial, the long-term benefits in labor savings, increased speed, and reduced handling costs often yield significant returns on investment.

Conclusion

In summary, conveyor roller assemblies are a vital component in the landscape of material handling systems. With their combination of efficiency, safety, versatility, and potential for cost savings, they are integral to modern industrial operations. As industries continue to evolve and adopt new technologies, the importance of optimizing and maintaining conveyor roller assemblies will only grow, reinforcing their role as a cornerstone of efficient material movement.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025