Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu guide idler

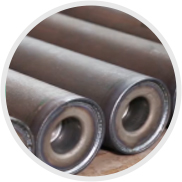

Understanding the Guide Idler A Key Component in Mechanical Systems

In the realm of mechanical engineering and design, various components play a crucial role in ensuring the efficient operation of machinery and systems. One such component, often overlooked yet vital for the smooth functioning of many mechanisms, is the guide idler. This article explores the significance of guide idlers, their functionality, and their various applications.

A guide idler is a type of pulley or roller that helps direct the path of a moving belt or chain in machinery. Its primary function is to maintain the proper alignment of belts, ensuring they do not slip off their designated path. By providing consistent guidance and support, guide idlers minimize wear and tear on conveyor systems and other mechanical assemblies. They are commonly found in applications ranging from industrial conveyors to automotive engines and even in household appliances.

The construction of guide idlers can vary based on their application

. Generally, they are made from durable materials that can withstand significant wear, such as steel, aluminum, or high-grade polymers. Some guide idlers are designed with bearings to reduce friction and increase efficiency, while others may feature a simple fixed design. The choice of material and design often depends on the operating environment, load requirements, and overall system design.guide idler

One of the most important roles of guide idlers is to support proper tensioning within a belt or chain system. Without adequate tension, the risk of slippage increases, leading to inefficient operation and potential damage to the components involved. Guide idlers ensure that the belt maintains optimum tension by distributing loads and mitigating the chances of bowing or misalignment. This is particularly crucial in systems where precision and reliability are paramount.

Furthermore, guide idlers contribute to noise reduction and enhance the overall lifespan of mechanical systems. By accurately guiding belts through their operational paths, guide idlers help in absorbing vibrations and impacts that could otherwise lead to excessive noise or mechanical failure. This is especially advantageous in environments where operational noise is a concern, such as in office buildings or hospitals.

In conclusion, while often taken for granted, the guide idler serves as an essential component in many mechanical systems. Its ability to guide, support, and protect moving parts ensures efficient and reliable operation across a multitude of applications. Engineers and designers must give due consideration to the selection and integration of guide idlers within their systems, recognizing their crucial role in enhancing performance and durability. As technology advances, the design and functionality of guide idlers will continue to evolve, promising even greater efficiencies in the future.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025