Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu roller guides

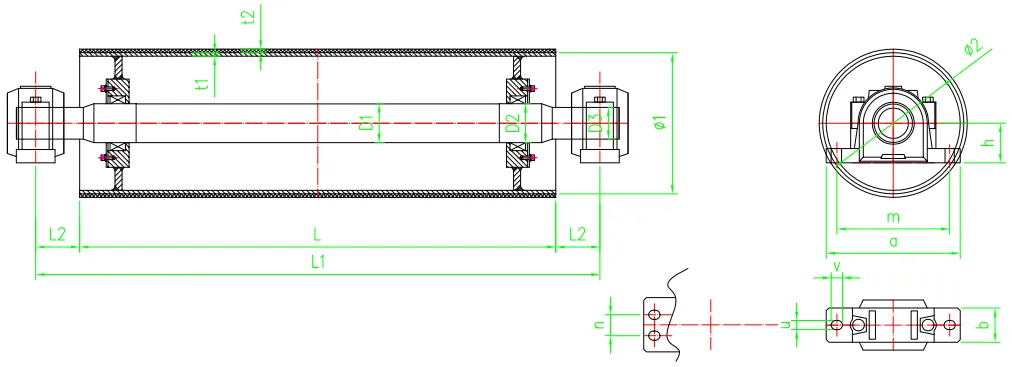

Understanding Roller Guides Essential Components for Smooth Motion Control

In various industrial applications, precision and efficiency are paramount. One critical component that plays a significant role in achieving smooth and accurate motion control is the roller guide. Roller guides, commonly used in machinery, robotics, and conveyor systems, provide essential support and guidance to ensure that moving parts can traverse their paths with minimal friction and maximal stability. This article explores the functionalities, benefits, and applications of roller guides, shedding light on their importance in modern engineering.

What Are Roller Guides?

Roller guides are mechanical devices that utilize rollers to support, stabilize, and guide moving components along a predetermined path. Typically composed of high-quality steel or plastic, these guides are designed to accommodate linear movements through a series of closely arranged rollers that reduce friction. By allowing components to glide smoothly over the track, roller guides contribute to the overall efficiency and durability of the equipment.

Key Features of Roller Guides

1. Low Friction One of the primary benefits of using roller guides is their ability to significantly reduce friction. This is achieved through the rolling motion of the rollers, which minimizes the surface area in contact with the moving part, leading to less wear and tear and increased longevity.

2. High Load Capacity Roller guides are engineered to handle substantial loads. Their robust construction allows them to support heavy machinery components while maintaining their structural integrity and performance.

3. Precision and Accuracy Due to their design, roller guides facilitate precise movements. This accuracy is crucial in applications where alignment and positioning are essential, such as in CNC machines and assembly lines.

4. Versatility Roller guides are adaptable to various configurations and sizes, making them suitable for a wide range of applications. Their flexibility allows engineers to customize them for specific operational demands.

5. Easy Installation and Maintenance Many roller guides are designed for straightforward installation, often incorporating pre-drilled holes and compatible mounting systems. Maintenance is typically minimal, though regular checks for wear and lubrication are advised to ensure optimal performance.

roller guides

Applications of Roller Guides

Roller guides are found in numerous industrial settings and applications, including

- CNC Machines In computer numerical control (CNC) machines, roller guides ensure that cutting tools move accurately along predetermined paths, enhancing precision during fabrication and machining processes.

- Robotics Robot arms and automated systems utilize roller guides to achieve smooth and controlled movements, crucial for tasks like assembly, welding, and packaging.

- Conveyor Systems In material handling, roller guides help manage product flow along conveyor belts, reducing resistance and allowing for seamless transportation of goods.

- Printing Equipment Printing presses often rely on roller guides to ensure the accurate movement of paper and ink application, contributing to high-quality output.

- Linear Motion Systems Many linear motion applications use roller guides for precise tracking and positioning, making them essential components in automation and manufacturing systems.

Conclusion

The importance of roller guides in achieving efficient, accurate, and smooth motion cannot be overstated. As industries continue to evolve and demand higher precision and efficiency, the role of these essential components will only grow. By understanding the functionalities and applications of roller guides, engineers and manufacturers can make informed decisions that enhance the performance of their machinery and systems. Whether in robotics, manufacturing, or material handling, roller guides remain a cornerstone of modern engineering solutions, enabling innovation and productivity across various sectors. Proper integration of roller guides into design and engineering processes can lead to significant advancements in operational efficiency and reliability, ultimately contributing to the success of businesses in competitive markets.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025